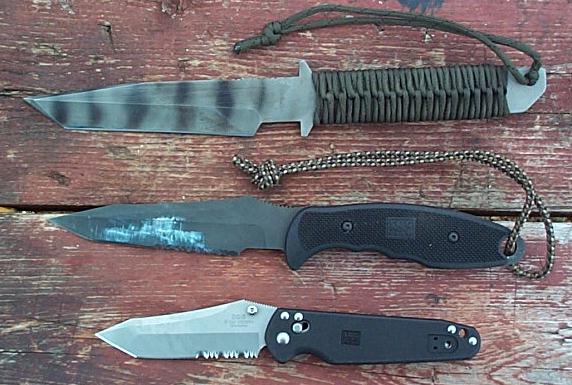

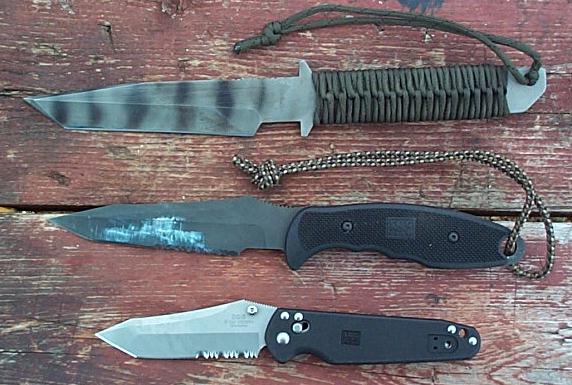

A shot of the X-Ray ision alongside a WB and Recondo :

The X-Ray Vision has 3.75 inches blade, with an overall length of 8.4 inches. The handle is made from Zytel and the blade is ground from 1/8" ATS-34 hardened to 58-60 RC. The knife has the "American Tanto" point geometry with swedges. The primary grind is a decently deep hollow sabre profile. Both the primary and secondary cutting bevels are slightly rounded, giving them a little belly to enhance slicing ability.

The Arc-Lock has been promoted heavily by SOG as a high strength lock [ref]:

Independent testing by an outside laboratory of the ArcLock came back with outstanding results. The lock was tested with pressure applied 1/2" back from the tip on the spine of the knife and did not fail until 338 pounds of pressure was applied. That equals 1,183 pounds of pressure directly to the lock before it failed. A significant achievement.

This description is problematic, 338 pounds is a force not a pressure. Assuming 338 pounds of force was applied 3.5" from the pivot, this produces 1183 in.lbs of torque at the lock - a high break point. However such tests are usually done with the blade clamped tightly which supports the pivot, and the force applied very slowly, so in more dynamic conditions the fail point could be much lower. As well, what isn't indicated is at what point is the knife functionally damaged, nor at what point can the blade take repeated loads without effect.

Moving beyond sharpness the Vision was used for about a week for food preperation (peeling slicing up vegetables and cutting meats), press cuts through thick cord, slicing up some heavy cardboard, slicing up tubing, and whittling soft and hard woods. Overall it was an above average in regards to cutting efficiecy. To guage the relative press cutting ability specifically the Vision and a few other blades were used to point some scrap wood :

| Model | Edge | Bevel width | Rank | |

|---|---|---|---|---|

| Type | included angle | inches | ||

| Mel Sorg Custom | v-ground | 11-13 | 0.035 | 100 |

| Vision | 28-32 | 0.038 | 63 (7) | |

| WB | 42-46 | 0.036 | 57 (9) | |

| Recondo | chisel | 52-54 | 0.038 | 22 (3) |

The performance of the Vision and Recondo is lower than expected from considering the edge profiles alone as both of these have a leverage disadvantage due to having to cut further out on the blade. Fatigue was not a factor here as the wood was small and frequent breaks were used. If the work was extended then the least efficient blades would suffer the worst [ref].

The above ranks represent well in general the relative push cutting abilities. However they will be effected by the size and structure of the maerial being cut. Different wood densities can effect the rank as can the magnitude of the force applied. On vastly different media the results could change significantly, the WB for example would drop a lot cutting thick vegetables as its thickness above the shallow sabre grind would be a drawback.

The serrated portion of the Vision would vastly out slice the high polished plain edge on many materials. On small rubber tubing for example (3/16" walls, 1" diameter), with just the weight of knife used to make the cuts, the plain edge part would take about 14-17 slices and the serrated portion just 4-7. The difference in "bite" can be readily felt. On large tubing (3" in diameter, 1/2" walls), this difference is a pretty significant one, as it takes a great amount of work with the the plain edge while the serrated edge parts the rubber pretty much like water.

With varies ropes similar performance was seen. On 1/4" poly, serrated part of the blade required *far* less edge length. On larger cord this difference was larger, a cut through 3/8" hemp (under tension) needed between 25 - 75 strokes with the plain edge depending on how much force was applied. The serrated edge required just 2 - 5 strokes with similar effort. Looping the cord and pulling both the serrated and plain edge parts through it; even with a very hard pull the plain edge part just scores the rope less than 1/8 inch deep, the serrated part on the other hand easily makes complete cuts.

To clarify, the plain edge doesn't slice very well as it was sharpened to high polish, and is also ground more obtuse than the serrations. If the plain edge was thinned out, and left at a more coarse finish, the slicing ability would be increased dramatically [ref]. Mike Swaim was the first to note such an effect on rec.knives and did a lot of work comparing the slicing performance of polished vy coarse edges, Joe Talmadge has extended that work significantly.

In general serrated blades don't push cut well due to the uneven surface, however on the Vision, as the serrations are ground much thinner than the plain edge (about half), and are closer to the handle which removes the leverage advantage, serrated and plain edges push cut at pretty much idential levels on thick vegetables, rubber tubing, and woods. As a specific comparison on wood :

| Model | Rank | |

|---|---|---|

| plain | serrated | |

| Vision | 100 | 100 |

| WB | 91 (12) | 96 (3) |

Note the performance of the plain and serrated sections of the Vision show no advantage compared to the WB when whittling woods.

After the above described work, the Vision was significantly blunted. It would tend to slip instead of cleanly slice on the harder materials, and required more effort on thin push cuts and could no longer handle precise cuts such smooth cuts through wrapping paper for example. The poly cutting was repeated to quantify the edge retention :

| Condition | Edge length | ||

|---|---|---|---|

| cm | |||

| 2.5 lbs | 700 g | 200 g | |

| NIB | 0.3 (1) | 0.7 (1) | 23 (3) |

| After use | 1.3 (9) | 8.3 (4) | 115 (10) |

The thread was supposed to be repeated as well, but was mistakenly left out. In any case the much reduced performance on the poly shows a clear loss in sharpness, specifically a degredation of 90+% on the 700 g load.

UPDATE : it would have been very informative to have at least one other blade used as a reference in the above.

The Vision was first given a light stropping on leather loaded with a CrO compound. While it did not return to the NIB performance, it made a gain of more than 350% on the poly (required 2.2 +/- 0.2 centimeters under a 700 g load). The thread cutting was also bought back to 140 +/- 14 g, close to the initial performance. Stropping continued to be able to restore the blade as it was loaned out to friends for feedback and periodically returned, one a week and stropping continued to make significant improvements on the sharpness as noted in the above.

After about the fourth week of use, the edge had suffered some light damage from opening paint cans and similar. In regards to ease of sharpening, 15 passes per side on an x-coarse eight inch DMT hone formed a burr along the edge except for a section which contained a hollow. One hundred 100 passes per side were required to bring the entire bevel flush. The edge was then finished at various grits to examine the cutting ability. Note the Recondo from SOG also showed the exact same inconsistency (hollow) in the NIB edge profile.

With each finish, the blade was sharpened three times (edges checked under magnification) and used to slice the 1/4" poly under a 440 g load. Twenty four cuts were made for each trial and the median used as the measure of sharpness. The performance was consistent for the three runs :

| Finish | edge required | Rank |

|---|---|---|

| cm | ||

| X-Coarse DMT | 2.0 (1) | 94 (10) |

| Fine DMT | 2.3 (2) | 84 ( 9) |

| X-fine DMT | 1.9 (2) | 100 |

| 25 strokes on CrO strop | 5.3 (4) | 36 (4) |

| 75 strokes on CrO strop | 18 (2) | 11 (2) |

as a graph :

Note the rapid loss of slicing ability as the edge is polished on the CrO loaded strop. On the rougher grits there seems to be a "sweet spot" of sorts at the x-fine DMT which gives the best result. Since the the load used was very light (440 g) it was not high enough to allow the larger micro-teeth of the coarser finishes to sink in to their maximum capacity and thus their potential for slicing aggression was being wasted as they were not achieving their maximum cut depth.

While all blades were pressed into the cord with the same amount of force (440 g), the x-fine finish drew smoothly across the poly with little effort, however the x-coarse finish required much more force on the draw and would just get stuck if the same level of force was used as was required for the x-fine DMT finish. Thus while more aggressive finishes can cut better, they generally need more force to do so. While the finer finishes also benefit from more force being applied, they don't see the same amount of benefit.

As an illustration, 3/8" hemp was cut with various finishes and the cuts made with low force and really heavy pressure. The amount of rope was limited so not all grits were used, the serrated portion of the edge however was used as a reference. The low force cutting was just a little above the weight of the blade, the high force was near the a maximum force pull generated by an elbow driven draw, sitting down with one foot on the cord to hold it in place.

The edge was again checked under magnification for each trial (agian multiple trials were used for each grit finish) and the sharpness was also tested on on 1/4" poly used a 700 g load to insure optimal sharpened at each level of finish. The results :

| Finish | Number of cuts | |||

|---|---|---|---|---|

| Low force | High force | |||

| Median | Rank | Median | Rank | |

| Serrations | 10 (1) | 100 | 0.75 (10) | 100 |

| X-Coarse DMT | 35 (3) | 29 (5) | 1.25 (20) | 60 (12) |

| X-Fine DMT | NA | 7 (1) | 11 ( 2) | |

| 50 on CrO strop | 25 (2) | 4 ( 1) | ||

Most obvious is the huge change in cutting ability as the force is increased. With low force, the edge produced by the x-fine DMT hone and CrO made no progress after 25 slices. More importantly, the increase in cutting performance isn't uniform. With low force the serration will out cut the x-coarse plain by much more than they do with high force. Under low force the micro teeth on the x-coarse finish are not pressed on hard enough for them to sink into the material efficiently. Note that the x-fine which cut the 1/4" poly very well, was far behind the x-coarse DMT finish on the hemp.

UPDATE : the serrations in the above were slightly dulled by the previous cutting. They were note sharpened as at the time the above work was done, no such small diamond or ceramic rod was at hand. NIB the cutting ability of the serrations would have been a small percentage higher.

UPDATE : push cutting ability falls pretty much directly as slicing ability is gained when moving from fine to coarse finishes. It would have been informative to compare the performance of the edge at the different finishes with push cuts on thread and the hemp .

In general, since the serrated part of the blade slices well, the plain edge part of the Vision was usally left at a high polish and thus optomized for push cutting. However on some materials like various fabrics, the serrations rip too much and the polished plain edge slips too much so a more coarse plain edge finish is optimal.

The Vision is ground from decently thick stock (1/8") with a swedge producing a thin tip suitable for precise cutting. It functions well as a box cutter, the tip penetrates easily and the acute edge allow an easy zip cut. The narrow tip also allows a wide variety of precision cutting, scraping and probing applications from rounding the eye out of a potato, working in the leg joints of poultry, to scraping gaskets. In regards to straightforward stabbing it sinks in various woods easily with light force. The main detriment being the uncomfortable clip which lowers the security of the handle and thus the force that I tend to put into the stab.

To look at the penetration in a more detail work was done with the Vision and the Recondo and the WB from Strider [ tip shot]. For light stabbing, the WB would not really penetrate readily due to the thicker tip, whereas the two SOG blades could poke a hole in a falling piece of cardboard for example. However for heavier stabbing, the WB had similar penetration to the other blades because it was much heavier and thus could generate more power on a swing, the handle was also more secure which meant less power was lost on a slip. On a phone book, a dozen stabs were made with each blade, the pentration was similar with each : ref. The performance was consistent for various woods as well.

The handle is decently ergonomic having an index finger cutout and a decent tapered shape which allows for a nice grip. However the inside of the Zytel slabs are not radiused which means as heavy force is applied they bite into the hand readily. The slabs also bend together under a tight grip. Finally the the skeletonized clip is far from comfortable.

The clip grips very tightly and goes on smoothly except the prominent thumb stud can catch depending on how loose the pocket. The clip is also reversible. The main drawback is that it is skeletonized and thus made significantly weaker. While pulling the clip over once centimeters away from the handle does not induce a permanent bend, the clip is bent very easily. The Vision was out on loan to a friend, and in less than two days it was returned as as the clip deformed :

The clip had snagged and then bent. The clip catches tight enough so that the retarding frictional force is higher than the force needed to deform the clip. This kind of bend will not happen in a full clip. According to the SOG rep on Bladeforums [ref], the clip is weakened in this manner intentionally to make it the fail point of the design not the attachment to the main body of the handle. The relevant queston would be what are the limits in both cases?

In addition, while breaks at the attachment point can be a costly repair compared to a clip replacement, based on this knife, the clip could be significantly stronger and still give before the attachment site is damaged. As well the a cutout design actually creates a hazard and greatly increases the chance of the clip catching which would just slip over the body of a smooth clip. A better design would be to just narrow the clip at one point which when stressed would readily deform.

The opening is not smooth, it can one handed opened via the thumb stud but the lock has to be disengaged to open the blade and this takes a decent amount of force, more polished interfaces would help in this regard. The lock passes spine whack tests with both light and fast and heavy and slow hits. It also is next to impossible to close with a tight grip. The only possibility is on a really hard stab with a reverse grip. If the pinky was positioned behind the release button and slipped on the stab it would be possible to hit the button and disengage the lock. However it takes a lot of force to move the release switch.

Based on the high promoted break points, the Vision was used to split some 2x4 sized lumber using a 550 gram piece of wood as a baton and using light wrist snaps to power the swing, the blade quickly suffered functional damage and now had vertical blade such that the the tip would shift by about two millimeters. Moving to some knotty wood, a dozen pieces were split varying the contact over the plain and serrated sections of blade. To drive the knife through the harder knots it was necessary to swing with elbow powered strokes, using the same mallet. This induced further vertical play in the lock, the point was now shifting about 3.5 millimeters, and would shake about in the open position with wrist flicks.

As a checking on how the Vision handled impacts into inclusions, a 3.5" common nail was hammered into a piece of pine, the the Vision was used to split the wood, coming in direct contact with the nail. With the same mallet four hits driving from the elbow again at near maximum force (hand never above the shoulder), destroyed the lock. The button that is moved to disengage the lock had come completely out of the mechanism and it was now stuck in a locked position.

After a few days out on the loan, as mentioned in the above the clip came back deformed both bent to the side as well as the two sides of the clip were no longer at the same height as the clip body had twisted as well. After a couple of weeks of use the knife was missing a small piece of the tip (0.5 mm) and the there was impaction along the secondary edge, both types of damage had happened when the knife had been used to pop the top of a one quart paint can. On the positive, the impaction steeled out, so the steel did not fracture but just deformed.

During the above wood splitting, on the clear wood the knife came through with no problems. On the knots the plain edge has no visible impaction or rolling, but the serrations were completely destroyed. All the points that had contacted with the knots broke off leaving a very jagged surface. When the plain edge part of the blade encountered the nail, it suffered impaction and fracture to a depth of over 1/2 the width of the edge. Here is a shot of some of the knots that were cut through as well as the piece of 2x4" used as a mallet :

On request (Ron Anderson from SOG), measurements were taken to estimate the contact energy during the splitting. By driving 24 nails (twelve 2.5" and twelve 3.5"), into a piece of 4x4 under controlled loads (weight drops) the amount of energy required was determined to be 51 +/- 2 ft.lbs, and 101 +/- 6 ft.lbs respectively. Using the mallet to drive in another dozen nails into the same wood, and comparing the results to the known energies, the impact energy of the swings came out to be 25 +/- 5 ft.lbs for the wrist pops and 45 +/- 8 for the elbow swings - a roughly 2:1 ratio.

After the lock had been functionally damaged work was done to gauge the strength of the tip and the blade body. Prying with the tip in a piece of 2x6", the Vision would break out of 1/4", and 1/2" stabs with no problems, but lost a large piece of its tip trying to pry out wood from a 3/4" deep stab. This also induce a slight bend in the main body of the blade, the top half was bent about 2-4 degrees to the side.

The knife was then pounded into the same piece of wood (cross grain) to a depth just above the primary grind right behind the secondary point. Using just wrist torque, driving with the heel of the hand, the knife was bent to the left. The handle readily deformed and then the Zytel snapped. Continuing, the handle bent at about 90 degrees to the blade, which had not significantly bent. Considering that the blade had not broken out of the wood, the applied force was not overly high.

With knife knife so bent, it was removed from the wood and with the blade blade against the wood, the palm of the hand was used to squash the handle against the blade. This was finished by just taking the knife in hand and squeezing it. No significant deflection was seen in the blade during any of the prying, the handle is far weaker and deformed and then broke before the force could come close to what is required to snap the blade. Here is a shot of the blade after the above :

The knife was straightened with caused the the liner on the outside of the bend to suffer stress cracks around the various holes drilled in it around the pivot point :

Bending it back again the liner sheared in half :

Pulling down on the liner that had broken away, it tore readily. Straightening the blade back out and attempting to close the knife tore the remaining liner across the front holes. The knife was now in two pieces :

A side on view which also shows the wood splitting damage to the serrations :

The liner was attached to the bottom of the handle was then bend to 90 degrees in a few places, which it could take this without snapping (it doesn't act like it was hardened). A shot of the various pieces :

The blade was viced one inch from the tip. Using a 10 inch Crescent Wrench it was bent sideways. Using a friend and a large protractor, the blade returned to true after 20 degrees as well as 30 and even 40, but snapped shortly at the point where it was fixed in the vice as well as across the hole for the thumb stud. The break was not clean, a piece about one millimeter deep, 2.5 millimeters wide and one centimeters high, had broke away from the of the blade right at the front fracture point.

Using a mild steel bar 0.75 inches in diameter and 11.5 inches long the edge of the largest piece of blade was popped while it was layed on a concrete floor. With just a hard wrist snap the edge broke readily. Working on the other part of the edge similar fracture could not be induced. Using an elbow driven swing, the edge again broke. Similar hits on the blade flats, six times, had no effect on the blade. A shot :

Many of the design choices are a compromise or trade off of properties, however some aspects of the X-Ray vision are just directly detrimental:

As well, if extreme strength of the lock is going to be promoted, a caution might want to be made in regards to issues with impacts.

The review of the Recondo from SOG contains more detail on several of the above performance aspects where it was used alongside the Vision.

Comments can be sent to : cliffstamp[REMOVE]@cutleryscience.com or by posting in the following thread on Bladeforums :

| Last updated : | 12 : 30 : 2005 |

| Originally written : | 05 / 30 / 2001 |