The X42 Recondo is a partially serrated Titanium Nitride (TiN) coated BG-42 fixed blade from SOG. The knife is 0.160" thick and 5.4" long. The handle is made from Zytel with an aggressive surface texture. The overall length is 10 5/8" and the weight 7 oz (220 g) . Here is a shot of the blade and the sheath :

The main interest in this knife was the steel, the high promoted hardness (62-64 HRC) should lead to excellent edge retention on most materials, however there might be issues with impact toughness and flexibility. There were some problems of this type noted on line [ref 1,2 and 3], and the response by SOG was not once which inspired confidence in the steel :

Usually, we do not recommend stabbing one's knife into wood. That does constitute misuse

From the SOG web page on the Recondo from SOG :

The X-42 Recondo was named after the Reconnaissance/Commando (Recondo) school established in Vietnam to train Special Forces in small unit, clandestine operations in hostile territory. Training included: survival, field medicine, land navigation, silent movement, photography, communications, helicopter insertion and extraction, and escape and evasion techniques. We have combined the spirit of this relentless training philosophy with SOG technology and state-of-the-art materials to create a truly extreme configuration. This geometrically faceted blade is an evolution of the original, mission-proven SOG. Always thinking forward, we have devised new techniques to produce a knife blade made with the incredible steel custom knife makers are raving about...BG-42. With an Rc of 62-64, BG-42 is extremely tough, hard, and durable and commonly used for years to make ball bearings.We are proud to offer several of our new designs with BG-42---The Ultimate Steel. The X-42 Recondo comes in our new ambidextrous Kydex sheath which is jump and military belt rated. It may also be ordered with SOG's black TiNi coating for low-reflectivity and enhanced edge holding.

In regards to the hardness, this varies depending on who is asked. The SOG rep on Bladeforums, Ron Anderson commented that 61-62 HRC was more accurate. Apart from the simple promotional statements "BG-42---The Ultimate Steel", there are some curious claims in the above. The coating does not form the edge so it will have little or no effect on edge retention (the possible lower drag of the blade profile isn't going to produce a significant effect). In addition, calling a high carbon, high alloy stainless steel at 62-64 RC "extremely tough", sets an odd baseline. How would 440C at 58-59 RC be then described "really extremely tough", or how about the A2 that Chris Reeves heat treats to the mid fifties for his One Piece line "really, really, really extremely tough"? Not to mention steels like 5160, 1084, L6, CPM-3V which are far tougher still.

The Recondo was used for about a week for various tasks; peeling and slicing up vegetables, slicing up meats and breads, press cuts through thick cord, slicing up some heavy cardboard, slicing up tubing, whittling soft and hard wood, to name a few. In short, the plain edge section needed an excessive amount of force to make push cuts even on light material and slicing was very difficult and slippage was common. Some specific relative push cutting ability can be inferred from the following in which the Recondo and a few other blades were used to point some scrap wood :

| Model | Edge angle | Bevel width | Rank |

|---|---|---|---|

| degrees | inches | ||

| Mel Sorg Custom | 11-13 | 0.035 | 100 |

| Vision | 14-16 | 0.038 | 63 +/- 7 |

| WB | 21-23 | 0.036 | 57 +/- 9 |

| Recondo | 52-54 | 0.038 | 22 +/- 3 |

in graphical format :

The custom by Mel Sorg out performs the Recondo by about 5:1 and even the heady duty WB out cuts it by more than two to one. The poor relative performance of the Recondo is due mainly to the edge which is very thick and obtuse. There is also a leverage disadvantage due increased distance from the start of the plain edge to the handle. While it is it also fairly blunt, that is not a major influence for this type of cutting, more on that below. As a side note, the effect of fatigue would cause the performance of the Recondo to drop even more with extended use [ref].

UPDATE : Note that SOG was asked specifically about the intended edge profile, specifically was it supposed to be this thick and obtuse, ignored all such questions (specifically Ron Anderson, who was the rep on Bladeforums at the time of the review). If a response had be given that the specifications were off on this sample it would have been modified to match the expected design.

The serrated portion of the Recondo would vastly slice better than the plain edge. On small tubing using just light force (1/4" walls, 1.5" diameter, using just the weight of knife), the plain edge part would take over twice the number of slices as the serrated part. The difference could be noted more readily on larger tubing which the serrated portion could slice through in one cut whereas it took multiple cuts with the plain edge.

An even larger difference in slicing ability was seen on cord. Starting off with some light cord, 1/4" poly, it was readily evident that the serrated part of the blade required *far* less strokes to cut through the rope. As the cord got larger, and more important harder, it became progressively more difficult to slice it with the plain edge. On 1/2" hemp, even with a large amount of force the plain edge needed over 100 slices to cut through the rope, the serrated part shredded it in 3-5 cuts.

A similar and more visually impressive demonstration of the relative cutting ability was evident by just looping the cord and pulling both the serrated and plain edge parts through. Even with a very hard pull the plain edge part just barely scored the rope, only cutting less than one sixteenth of an inch deep. The serrated part on the other hand easily cuts completely through the rope in an explosion of hemp fibers and the stroke doesn't even travel along the full length of the serrations.

In general the drawback of serrations are the low push cutting ability, however due to the very thick and obtuse plain edge on the Recondo, the serrated section of the blade actually will out push cut the plain edge part. For example repeating the above wood whittling, the serrated section of blade showed a performance improvement of 263 +/- 31 % over the the plain edge version. This is due to the grind of the serrations being about twice as acute, as well as losing the leverage disadvantage as the cutting is done closer to the grip.

Note the cutting advantage of the Recondo isn't due to a greater sharpness, tested on the thread it is so dull the thread simply breaks at at around 700 +/- 50 g. Aside from the lower angle, in regards to slicing the cutting ability of the serrations is enhanced by the high pressure of the contact points and the curvature induces high forces on the materials as it ramp around the curvature. Regarding serrations vs plain edges in general, the slicing ability of the plain plain edges can be vastly increased by leaving the finish at a rougher polish [ref].

As a side detail. the serrations on the Recondo are sloped backwards like the teeth on a Japanese saw. They are thus much more aggressive on the draw than on a push. In general, they don't cut well compared to other patterns such as those by Mission or Spyderco. The serrations on the SOG Vision also out cut by more than 2:1 the serrations on the Recondo on thick cord and rubber tubing. Though the Recondo serrations could be used on some materials more effectively than the Vision serrations as they don't tend to catch as much. Many types of fabrics are very difficult to cut through with the Vision for example, whereas the Recondo's serrations can make much smoother cuts.

After the above work the sharpness tested was repeated on both knives. During the work both blades were used to cut an equal amount of material, however as the cutting ability of the Recondo was much lower than on the Vision, it often had to use many more cuts to achieve the same task. Recondo had to do much more work. The results which include a push cut through light thread and some slicing of 1/4" poly under three different loads :

| Model | Edge | Thread | poly | |||

|---|---|---|---|---|---|---|

| angle | width | 2.5 lbs | 700 g | 200 g | ||

| Degrees | Inches | grams | cm | |||

| Vision before | 14-16 | 0.038 | 100 +/- 8 | 0.3 +/- 0.1 | 0.7 +/- 0.1 | 23 +/- 3 |

| Vision after | NA | 1.3 +/- 0.9 | 8.3 +/- 0.4 | 115 +/- 10 | ||

| Recondo before | 52-54 | 0.038 | 242 +/- 17 | 4.0 +/- 0.4 | 19 +/- 1 | 73 +/- 9 |

| Recondo after | 280 +/- 10 | 4.6 +/- 0.7 | 22 +/- 2 | NA | ||

The thread cutting on the Vision was not done as a mistake. However looking at the poly, while the edge had degraded it was still far sharper than the Recondo by about 3:1. The main reason for the lower degradation of the Recondo is that fact that it was quite blunt to begin with.

Being light with a neutral balance, with a thick and obtuse cross section, the Recondo chops poorly even with a lanyard and a grip around the edge of the handle. For example chopping up a small piece of pine, a few months seasoned, the Recondo was out chopped by over 2.5:1 by the WB from Strider. The WB has a similar geometry but is more forward balanced and significantly heavier :

For comparison, a quality chopper like the Busse Battle Mistress, will out chop the WB several times to one and is thus out chops the Recondo more than ten to one. The Battle Mistress is easily capable of taking down small trees with a similar amount of chops that it takes the Recondo to go through the branches.

The Recondo can be used with a baton to cut larger wood. The tip can be pounded into the tree and worked around until it is weakened enough to crack, or it can be cut in the same manner as it would be chopped using the Baton to drive the blade into the wood. Getting specific, with a baton, the Recondo can out chop the WB used under its own power.

As a curious aside, the plain edge part of the Recondo only has about 49 +/- 7 % of the chopping ability of the serrated edge section (comparing the two on a couple of dozen pieces of scrap from about 1/2" to 2" in size). The plain edge is further out on the blade and thus has greater velocity, and as noted serration patterns in general are not great at push cutting due to the "wavy" profile, however because the plain edge is so obtuse this swamps out all other aspects and the the penetration is much lower than on the serrated section.

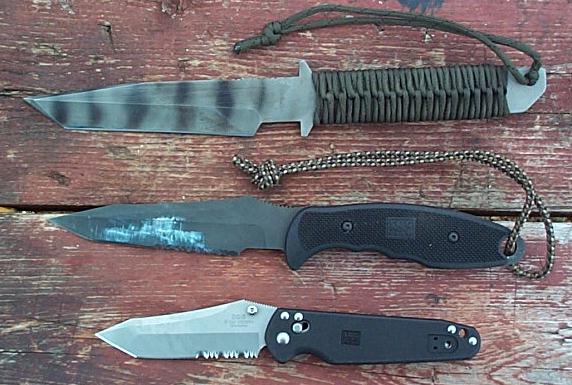

Even though it is of fairly thick stock (3/16") with a shallow primary grind and no distal blade taper, the Recondo offers a decently thin point due to the additional tip grind. A shot of the tip profiles of the Recondo, X-Ray Vision and WB :

Doing some stabbing with these knives, with light poking, the WB was far behind. However when heavy swings were used, its larger mass (306 g as opposed to 215 for the Recondo) allowed more power to be generated and it could get similar depth as the other blades. They were all similar on heavy stabs into phone book for example.

Similar performance was seen on woods, for example the Recondo would sink to 3/4" to one inch deep into a piece of seasoned pine, and the WB stabs would cluster around 7/8" deep on the same piece of wood. The performance of the WB was also enhanced by the more secure grip, any slippage will cause power to be lost. Thus the Recondo has a more efficient tip profile than the WB, but the WB has overall similar penetration abilities due to being heavier with a more secure grip.

Looking at tip strength, both knives were used to dig through a piece of one inch thick board with stabs resulting in about a half an inch of penetration. Moving on to thicker wood (2x4) and harder stabs about 3/4" penetration, the WB still easily handled the digging, but the the tip on the Recondo quickly broke, losing one cm. Thus while the slimmer tip on the Recondo does give it greater penetration, it does cost it a significant amount of strength.

Of course if the stab depth would have been kept at the lower level, the Recondo would have still been fine, but then the WB would have been much more efficient due to being able to move more wood per stab.

The plain edge on the Recondo was sharpened using some diamond hones from DMT. The edge was not ground evenly by SOG, there was a large patch about 0.5 cm long that was lower than the rest of the bevel and thus the bevel had to be ground flush before that patch would even be hit by the hone - this took about 15 minutes. Finishing with a a 1200 grit DMT hone the blade would shave but not that smoothly. Finally it was polished extensively on a strop loaded with CrO compound, 20 strokes per side. The edge was tested for sharpness with both finishes :

| Edge condition | Thread | 1/4" Poly : 700g load |

|---|---|---|

| Required force | Edge length required | |

| grams | cm | |

| NIB | 242 +/- 17 | 19 +/- 1 |

| 1200 DMT | 235 +/- 13 | 3.0 +/- 0.4 |

| CrO loaded strop | 215 +/- 8 | 16 +/- 2 |

Both edges outperform the NIB finish, the 1200 grit DMT finish is the more aggressive slicer by a significant margin, outperforming the other finishes by over 5:1. With the freshly honed CrO shaving sharp edge the above push cutting and chopping was repeated with no improvement on the NIB performance. This would be expected as the geometry was the critical influence for most of that work.

During the above cutting and even chopping there was no deformation or chipping of the plain or serrated part of the edge. The Recondo was used with a baton to split a few small pieces of wood which it handled fine as did the 52100-MEUK which has a much thinner edge profile. (in retrospect the baton work should have been repeated with serrated portion of the Recondo, this caused heavy damage to the SOG X-Ray Vision)

To check hard contacts the Recondo was struck with a mild steel pipe one millimeter thick, one inch in diameter, three feet long) while it was held in hand. The blade saw half a dozen impacts on the spine, on the flat and on the edge. The plain edge chipped out with almost every contact with the largest chip being over one millimeter long and about as deep. The serrations were completely destroyed. The coating held up well and did not crack.

Due to the checkering on the slabs, the thin profile and aggressive ridges on the pommel it was impossible to get a solid grip against the the hits on the flats and edge. So it was stuck into a piece of 2x4" and then hit on the flat with the bar. The blade shatter immediately and flew about 15 feet. It broke at the bottom of one of the ridges on the thumb ramp. There are a lot of sharp corners on the blade, very little in the way of smooth contours and this greatly lowers durability. Here is a shot of the Recondo after the tip and main blade fracture :

| It was later asked about the level of these impacts, using standard weight drops they were estimated at 100 (25) ft.lbs |

As a comparison, the above was repeated on a small stainless fillet knife, unknown stainless steel, 440A class. The blade is made from 1/16" stock and has a full flat grind, with a very light distal taper and a thinner and more acute edge than the Recondo. Here is a shot after the pipe impacts :

The edge of the fillet knife (22 degrees per side) did not significantly impact under the pipe blows, though was blunted. It fared much better than the plain and serrated edge on the Recondo which had more steel and yet still fractured, showing a much lower impact toughness. The fillet knife was also stuck in the wood and whacked with the pipe. The knife did bend in the tip (the blade is about 0.040" thick in that region) but stayed in one piece :

A piece of the Recondo tip leaning against a pen alongside the fillet knife tip for perspective :

| Horrible lighting, but the point is clear that the fillet knife has a much thinner point. |

The blade on the fillet knife did come loose from the handle on the first hit. It has a short partial tang (less than one inch long) and on the next hit the handle came off. The wooden handle also cracked from the impacts. The blade itself was then smacked the blade a few more times with no significant effects. Note the blade does not always fly out from the wood, it can actually snap backwards depending on where you hit it.

In regards to prying, the middle section of the Recondo blade was locked in a vice and a ten inch Crescent Wrench was used to grip the end. The blade broke twice at low angles of flex, 20-25 degrees. On the second snap, the break was so violent that sparks actually came from the vice. Not a lot of force was used, one hand wrist torque, however the wrench have another 4-6 inches of additional leverage over the handle had it still been attached.

The blade bits were also on the concrete floor and the edge popped with a small hammer using just wrist snaps. The steel violently shattered into bits, four large pieces and a bunch of smaller ones that were never located. It was then popped the blade a few times on the flats which it held up to fine. A shot :

This was repeated with the fillet blade which did not fracture even under a lot harder hits. under extreme impacts it will just cold work thinner. The fillet blade held up better, not only because it had a much tougher steel but also because the geometry is much more durable under those kinds of impacts. On the concrete floor the flat grind of the fillet blade allowed the back to make contact all along its surface whereas the hollow grind of the Recondo however meant that it was only in contact at the top and bottom of the grind and thus under impact had a much weaker structure. The exact same aspect is critical when twisting the blade, it is more likely to break the primary grind if the knife is hollow ground than if it is flat (or convex), as there is no support under the pressure point on the opposite side of the blade. Of course there is a tradeoff with going with a tougher stainless steel which is loss of wear resistance and strength. Note as well, that since the fillet blade could flex when impacted, it could absorb a significant amount of the later impacts when it was stuck in the wood. It would have been more informative if it was of similar geometry to the Recondo.

UPDATE : In general as these reviews are a personal hobby not contracted evaluations, there are monetary limits. Obviously there would be better blades to use as benchmarks. The fillet blade was just the only "tougher" stainless knife available at that time.

The TiN coating held up very well to abrasion and saw no effect of of the cutting and chopping. Even the pipe and hammer hits did not cause the coating to come off in extensive amounts. However after nine hours in a salt water solution (one tbsp of table salt in two cups of tap water), the Recondo showed significant corrosion along the fractured edges, rusting being enhanced by the rough texture. It also showed significant corrosion along two parts of the actual edge, and in two places the corrosion went out along the coated portion of the blade for about 0.5 cm. As well there were several patches of the coated flats that had a light orange tinge to them.

To clarify, significant corrosion means rusting that is opaque and cannot be removed in the majority (75%+) by a simple wipe with a damp cloth and cleaned up 100% with a light scrubbing with a worn Scotchbrite pad. The fillet blade was also soaked and only showed a slight discoloration along the tang which could be rub off with a finger and remove completely with a couple of passes with a worn Scotchbrite pad.

The handle has an aggressive checkered surface which gave a very secure grip, similar in performance the Project from Reeves. However partial grips during chopping quickly wore a hole straight through the outer layer of skin. If the grip was a little smoother in that region it would be more functional for chopping and the overall loss of security would be low in a full grip as there would still be a lot of texture available. The overall ergonomics also had issues. While the cutouts did match grip well, the swell behind them was far out of line. Using the blade in reverse grip for draw cuts was very uncomfortable due to the shape which is obviously optimized for the opposite handle orientation.

The handle was eventually subjected to impacts from a 600 g mild steel bar, about 64 (9) ft.lbs. The slabs resisted fracture until it was struck just above where the tang was hollowed out. In regards to cut and wear resistance it is far greater than Kraton, which not only tear and easily be cut, but will just degrade quickly during normal use. The grip on the Recondo cannot be functionally damaged even under a very heavy slices 75 (5) lbs which just score the surface. The handle was later destroyed by a light swing from an eight lbs maul. The grip material and tang fractured extensively, the tang in about a half a dozen places and the grip about twice as much.

The Kydex sheath is well formed to the blade and holds it securely without excessively hampering the draw. The belt loop can be unsnapped so you can attached or remove it easily. On the downside Kydex does not have a long lifetime in regards to excessive flexing based on the half a dozen pieces sheaths I have used, so care needs to be taken for the loop in that regard, a webbing loop would be much more durable. As for construction, this style is the worst way you can form Kydex in regards to durability. A wrap around sheath with smooth contours is a much more durable design.

This knife came with a very blunt initial edge and even after sharpening cut poorly due to a thick and obtuse edge and shallow primary grind. The chopping ability was also low due to the low weight and neutral balance. The Recondo also didn't fare well in regards to heavier work, breaking under low angles when subjected to lateral loads, and fracturing easily under impacts.

Usually thick edges knives will be reground to examine the potential for cutting performance however this knife had so many performance problems and was so incoherently designed there was little interest in doing do. Even with a more optimal edge, the shallow primary grind would still be a problem, the grip was not comfortable, the coating didn't offer significant protection from corrosion, the Kydex sheath wasn't a quality one, etc. .

The SOG rep on Bladeforums at the time of this review commented that the expected behavior of the Recondo is as described in the above :

Considering the condition of the Recondo, the most likely cause of the multiple fractures are consistent with the blunt force trauma outlined in Cliff?s article

UPDATE : When returned to SOG the knife was hardness tested and found to be 62 HRC. The hardness of the Recondo was later lowered to ~58/60 HRC.

UPDATE : SOG later designed a knife which had a much higher cutting profile than the Recondo, the Field Knife. Basically a fully flat ground Recondo, with more belly. No edge specifics were given, and ironically, and unfortunately the edge hardness was lowered. A light duty utility knife would actually have benefitted from a higher hardness. Once again, incoherent design.

Comments can be sent to : : cliffstamp[REMOVE]@cutleryscience.com or by posting in the following thread :

For additional information you may be interested in having a look at

and stop by SOG's webpage or the SOG forum forum on Bladeforums.

Vicing : the argument was raised by Ron Anderson that more "natural" work would be preferred such as jam the knife in a tree and pry with it. This arguement isn't consistent as he also argued in other places against that exact type of work. Of course "real work" was also done with the knife, it was used to dig in wood for example and the point broke in a similar manner as to how the main body broke when the knife was flexed.

Hard impacts : aside from martial applications, the edge of the blade can see very energetic impacts from contacts off of inclusions. These hits can also generate much higher pressures than the pipe hits because of the much lower contact areas. Some knives can handle this work, some can't.

I have split 2x4's, 4x4's and 60 or so 10' diameter cedar logs (pounding the knife through with a big rock) with no damage to the knife.

which is in reference to a TAC-11 from Tom Johanning being reviewed by Dan Kohlstrom. Note also that the pipe really was only mild steel, it actually deformed under the impacts. Here is a shot of a couple of cuts made through it with the PAB from Strider which has a thinner edge bevel and deeper hollow grind than the Recondo :

The pipe had to be flattened by hammering with the spine of the PAB before it could be readily cut. The impact pressures on the PAB were also much higher as the chopping was into the thin section of the flattened pipe which was cut to a depth of about half an inch. The edge on the PAB is also not as thick as on the Recondo . The pipe was finished being sectioned using a Norse Tomahawk from Cold Steel, which also has a decently thin edge. The Tomahawk suffered slight impaction, about 0.2 millimeters, just visible. The PAB had less denting, about 0.1 millimeters, very hard to see, due to being a lot harder with a more obtuse edge angle (20-22 degrees). Neither blades chipped, however both were very blunt in the contact areas.

Repeatability, Steps were taken whenever possible to make the work more controlled. Not all such details were noted, for example during the pipe hits, the pipe was gripped at the very end and a hard snap was done from the shoulder with the pipe held perpendicular to the wrist at the start. Maximum effort was used on the hits and a short rest was given in between the hits to eliminate fatigue. The contact point varied less than one centimeter on the pipe, with the end position of the swing being controlled by my judgment of my forearm being perpendicular to the ground.

| Last updated : | Jun 25 :2004 |

| Originally written : | May 2001 |