The SUB Sniper is one of a family of small (two inch blade) knives offered by Lynn Griffith. They are made from 1/8" thick ATS-34 stainless steel stock with an overall length of six inches and come with a Kydex neck sheath standard. This sheath came with an additional loop for belt carry. Golden Micarta was chosen instead of the standard black to make it more "friendly".

The blade was straight with even primary grinds. The edge bevels were a little uneven by eye. The whole knife including the tang and lanyard eyelet was bead blasted to match the finish of the blade. The color of the cord also matched the Micarta, which had a very aggressive surface texture which felt very secure without being abrasive.

The sheath held the blade securely with no rattle, and there was a thumb ramp for a smooth push-off draw. Here is a shot of the Sub-Sniper with a couple of other blades for reference :

From top to bottom; MEUK, Sub-Sniper, MNK . This picture was taken after the Sub-Sniper and MNK had been heavily used and sharpened.

Over a period of a few days the Sub-Sniper was used alongside a small custom utility blade in D2 that was made by Mel Sorg. In short the D2 knife readily out cut the Sub-Sniper due to its much thinner and more acute edge.

In order to obtain a more quantitative viewpoint, both knives were used for some whittling on various woods. The scrap was mostly small wood from about one inch square to 1.5" by found inches. The cutting was done at maximum effort and frequent breaks were taken to insure that the effect of fatigue was kept to a minimum. The following table shows the relative ability of the two blades, the rank presented is the median of the ratio of the number of slices needed to cut away a given section of wood.

| Model | Edge angle | Bevel width | Ranking |

|---|---|---|---|

| degrees | inches | ||

| Mel Sorg Custom | 12 | 0.035 | 100 |

| Sub-Sniper | 22-27 | 0.032 - 0.039 | 49 +/- 2 |

The edge angle on the Sub-Sniper was lowered to increase the cutting performance using an x-coarse silicon carbide waterstone. The edge was then honed with one micron sandpaper and it would push shave cleanly. The increase in performance with the modified edge angle was obvious throughout a few days of carry. The wood cutting was repeated to get a more concrete representation of the increase in performance :

| Model | Edge angle | Bevel width | Ranking |

|---|---|---|---|

| degrees | inches | ||

| Mel Sorg Custom | 12 | 0.035 | 100 |

| Sub-Sniper | 11-13 | 0.083 | 85 +/- 5 |

With the more acute edge the SUB Sniper is in the same class as the D2 custom by Mel Sorg, which still has a slight advantage due to the thinner edge, and greater handle size. Moving beyond wood and doing some cutting with various materials such as vegetables, thick rubber, heavy cord, etc., the relative push cutting ability of both blades is very close and considerable care would need to be taken for the slight performance advantage of the D2 custom to be noticed.

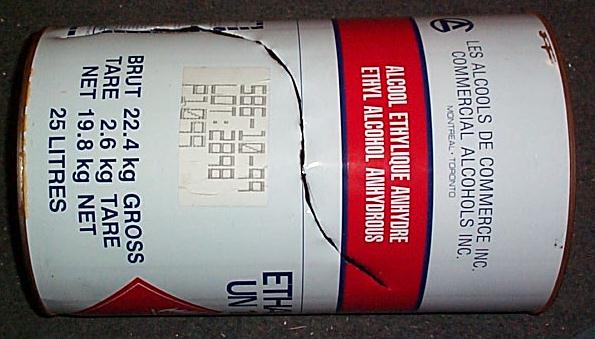

With the lower edge angle did not cause any problems cutting soft to moderate materials even when high force was used. To examine the limits, a large cut was made through a a 25 L can. The Sub-Sniper was stabbed into the can to start the cut and it was used similar to a can opener and as well just slicing with heavy pressure to make the cut. Using just heavy slices was the best method in terms of reducing the amount of damage the knife but it proved to be very fatiguing. The can :

Overall the blade held up well and took only minor damage. On the sixth stab a small amount of the tip snapped off, around one millimeter . During some of the twisting the edge chipped in a few places, about 0.5 millimeters deep and a couple of millimeters long. At the end of the cut the blade had zero slicing ability and was just tearing through the metal. The damage was just large enough to be visible, but not enough to show up in a picture.

During the sharpening to remove the damage, the edge angle was lowered again to produce an edge profile of about nine to eleven degrees per side. The durability was still enough for any normal cutting chore (outside of hard plastic, metals and bone) even when heavy force was applied.

UPDATE : It would have been informative to do this with another knife for a benchmark.

With the nine to eleven degree edge, the Sub-Sniper was used for an extended cutting alongside the Traditional Tanto from Running Dog Knives to examine edge retention on woods. The Sub-Sniper had significantly greater edge retention : ref. Both blades required just a couple of minutes of work to return to full sharpness with the Traditional Tanto responding stronger to alignment work with a steel which would be expected as the steel is softer.

While a thicker handle would be preferred for extended periods of heavy use. However as is, the slim profile reduces the weight and printing making it easier for concealed neck carry. In regards to the three finger grip length. On really heavy cuts there will be a lot of pressure put on the contact point under the very end of the grip as this is what generates the counter torque necessary to push the blade through the material. For a full length handle the contact pressure is *much* lower as the contact area is significantly greater. The texture of the Micarta was found to be very secure without being abrasive, hard cutting was no trouble even when the handle was wet.

As a final point on ergonomics, for a lot of precise draw cuts, a grip can be used which places the index finger hooked over the spine and the cut is made by rolling the fingers down or torquing the wrist towards the inside of the elbow. This grip is used a lot for shaping wood and can be used for a lot of light cutting in general. This type of grip works best on a knife with a a strongly curved spine. The Sub-Sniper, with the full curved spine is much more comfortable to use in this manner than for example the Traditional Tanto from Running Dog Knives with its flat spine.

The sheath holds the knife securely with no rattle, but at the same time the knife can easily be drawn using the thumb to pop the knife out of the sheath. The knife is small and light and does not print significantly when worn.

In short, the SUB-Sniper generated exactly the hoped for response. The combination of the small size plus colorful handle seem to not make people see it as a "weapon".

The Sub-Sniper was later extensively compared against the a MEUK from Allen Blade and Ed Caffrey. The edge was further reduced down to less than nine degrees per side and once freshly sharpened the blade easily pops hairs and will even catch free standing fine hair. Some standard cutting on hardwood dowels shows the blade to be performing very well. With the lower edge angle and acute tip profile due to the Wharncliffe profile, the tip has broken (fraction of a millimeter) doing some light tasks such as carving hard plastics. The tip was made more robust, altering to more of a sheepsfoot geometry by increasing the curvature of the spine.

Comments can be sent to : cliffstamp[REMOVE]@cutleryscience.com or by posting in the following thread on Bladeforums :

Lynn

has a website which can be checked

for more information on his knives.

| Last updated : | Wed May 14 12:32:35 NDT 2003 |

| Origionally written : | Fri Jul 20 15:14:40 NDT 2001 |