- Lum Chinese

- Paramilitary (heavily modified)

This review consists of :

Knives :

This review consists of : |

|

Basic specifications :

Spyderco ad copy :

Spyderco Chinese Folder by Bob Lum

Glass fiber manufacturing is part chemical, part mechanical. Strands of glass and carbon are drawn into fibers then heated to high temperatures to expel the majority of non-carbon atoms in a process called carbonization. The process creates filament-like fibers composed of tightly woven chains of glass/carbon that when laminated into sheets makes exceptional knife handles that are lightweight, visually pleasing and wear-resistant.

Conventional glass fiber is woven, basket-like, horizontally and vertically but our Japanese makers have developed a new weaving process that creates circular and swirled fiber patterns called Nishijin. Spyderco combines a Nishijin glass fiber handle, with custom knifemaker Bob Lum's Chinese Folder design resulting in an Asian-influenced CLIPIT exuding the simplicity and function of traditional Chinese cutlery in a modern superior cutting tool.

Inside the Nishijin handle scales are full-length liners and a Michael Walker LinerLock'. The blade is wider at one end, tapering to a point like a leaf and offers a pointed tip for detailed, precise cutting and plenty of width across the blade for serious cutting chores. The VG-10 steel blade is full flat-ground with a PlainEdge cutting edge and a swedge ground from the spine adding style and lessening overall weight. A black three-screw metal clip carries the folder right-handed tip-up/tip-down.

A quick YT/web scan :

The Lum uses a glass fiber scale which is a fairly unique material, not commonly used in knives :

The defining feature of this knife is its luxurious glass fiber scales. Its earlier incarnation came in more common aluminium scales, and it is truly incredible how a simple material change turned a standard knife into a functional work of art. Again, the handles on this knife are made of glass fiber, not carbon fiber, which is a common mistake to make. The key difference is that strands of glass, and not carbon, are used in the process of making these handles.

The Lum, like many of Spyderco's collaborations is obviously strongly aesthetically designed, especially in this case where making the knife visually striking was a critical goal. This seems to have been very successful as feedback on the design from a visual point of view are very positive :

To set the record straight, the Spyderco Lum Chinese Folder is a gentleman�s knife through and through. It is absolutely gorgeous, but its intent hardly seems to be hard use. When designed, I don�t believe that this knife was supposed to be used for cutting cardboard or whittling sticks like other less pretty knives and as such, I am not going to judge it in this capacity. Instead, I view the Lum as knife art and while still very functional, I believe this knife is best suited for a suit pocket at a formal occasion or in the pockets of your groomsmen at your wedding reception. That is to say, it looks downright impressive and is one of the few knives that can double as a fashion statement much like a high end wristwatch or fancy cuff links.

A big point in regards to the design which clashes, a least lightly, with function is the grip and general design of the blade which forms a gentle curve both open and closed.

Although comfortable in the hand the absence of textured scales, a finger choil and jimping may restrict this knife to lighter cutting duties.

But again, it has to be kept in mind that this is a folder which was geared towards aesthetics over raw functionality.

On 3/8" hemp :

Now in order to interpret these numbers it is needed to compare them to other knives. At the extreme end, these cuts can be made with much lower force. At the very limit a slice can be made with 4-6 lbs on a 2" draw but that requires a near zero bevel with a very low angle (6-8 dps). These numbers are in general very low for a production knife showing the cutting ability is very high, at least on slicing rope.

On carving 1" basswood dowel compared to the #1260 Mora, making 2" points with light force (10-30 lbs) :

On the same dowel with heavy force heavy force (50-70 lbs) :

These numbers are easier to make sense out of as the Mora is a very well known example of a knife which is designed/promoted for exactly this use and the Lum, being able to match the Lum shows again it has solid cutting ability.

As a very light check on edge retention, in extended use, 1000 slices, on basswood, pine and hickory flooring there were no issues with edge damage, no rolling, chipping or excessive wear however there were some ergonomic issues :

But an argument could be made that this really isn't the intended use of the knife.

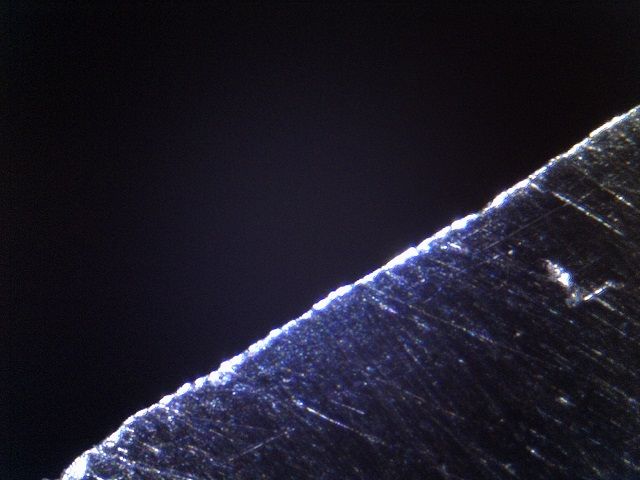

As noted in the image on the right, the wood cutting had no significant effect on the edge. Again though, this is a very low stress check of course and it is mainly to see if there are any significant issues with the knife such as :

Neither of which appear to be the case as the edge was not significantly effected.

In the kitchen it often proves its utility because it is one of those knives that can be carried anywhere easily and thus at a friends watching them struggling to use dull and never-sharpened knives, the Lum, though not ideal for a kitchen knife easily outperforms such blades.

The high flat grind and relatively low edge angle/thickness will allow it to compete with even properly sharpened decent knives in the kitchen though it is awkward for peeling due to its width and a little less than ideal obviously for working to a cutting board.

But it does show readily how a sharp knife, even if less than

ideal shape can also do extremely well compared to one which isn't.

It does however show its limitations fairly quickly if it attempted to be used in a role much beyond a paring knife as the lack of length makes it awkward to be used for :

This work is possible of course, but awkward as multiple cuts have to be made and this is really pressing beyond the expected scope of work of this knife.

A little utility work, again shows the cutting power of the :

But the handle starts to have ergonomic concerns almost immediately.

A little brush work, show again the many positive aspects of the Lum from a performance perspective :

Now light grass cutting does not demand much from a blade geometry wise and really just requires a high sharpness, but the Lum does this kind of work much better than something like the AK-47 from Cold Steel example which adds nothing functional with the heavier weight and it just much more awkward in hand.

In contrast though, the same properties which make it excel at such work lower its performance on heavier wood cutting. The

give is little to no chopping ability or do to a snap cut and thus on such woody vegetation it is left to just push cuts and it is significantly less capable than a heavier folder in terms of cutting efficiency and general fatigue rate.

Now it is much more capable than the Spyderco Air for example and can easily make quick work of minor jobs such as taking small alders away from every greens and it isn't so delicate as to be concerned about any aspect of the work. However the lack of snap chopping ability does reduce its functionality to just emergency / occasional type use which again isn't that surprising and certainly not a negative as it is mainly a gentlemans folder not a hard use wood craft knife.

After a decent amount of work was done with the Lum and no significant

damage was noted to the edge it was reground to optimize the edge to maximize

the edge retention, cutting ability and ease of sharpening. This is done by

adjusting the edge thickness, edge angle and apex bevel all to the minimal

levels to ensure that it just has the minimum required durability which will

maximize all of the other properties.

The first step was to flatten the grind to a close to true zero with a Suehiro 'Chemical' 320 waterstone which is an old style softer waterstone which requires extensive soaking, otherwise it won't release slurry and will tend to glaze and cut slow. It also needs a fair amount of force until the slurry is generated at which point it is self-sustaining.

Grinding flat to the stone generated an edge curvature of 5-6 dps due to the light wear in the stone and small random deviations in hand sharpening which increased it over the 3 dps primary grind. The edge was then polished with a Naniwa Aotoshi 2000 to ensure the apex would form clean at that low angle and it did. The Aotoshi is also a very soft and muddy stone but doesn't require soaking and can be used just wetting the stone and grinding.

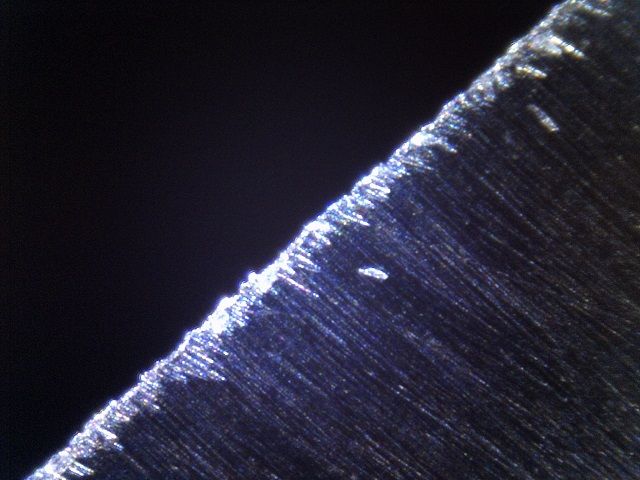

The image on the right shows the application of an x-coarse DMT 15 dps

micro-bevel. That picture is 1 mm wide, so that micro-bevel is ~30 microns or

~ 1 thousands of an inch wide, barely visible.

In order to check the edge for durability it was used for the hardest task that is reasonable given the expected uses of this knife which is cutting very heavy cardboard. In this case a mix of 1/8" to 1/2" cardboard was cut at a fairly rapid speed of about one foot per second.

The results were near ideal showing :

Which indicates that the geometry has enough durability to prevent gross

damage and allow blunting to take place by a slow, consistent process.

As a point of curiosity the knife was then used beyond the expected scope of work just to see what would happen in extremes by cutting through globs of set epoxy in very thick cardboard. This puts a lot of lateral force across the edge as the knife cuts into the epoxy, it starts to rip out of the cardboard, and then it twists across the knife edge. With the original grind this work would be no issues for the knife, but it likely is for the new grind which has a much lower durability limit.

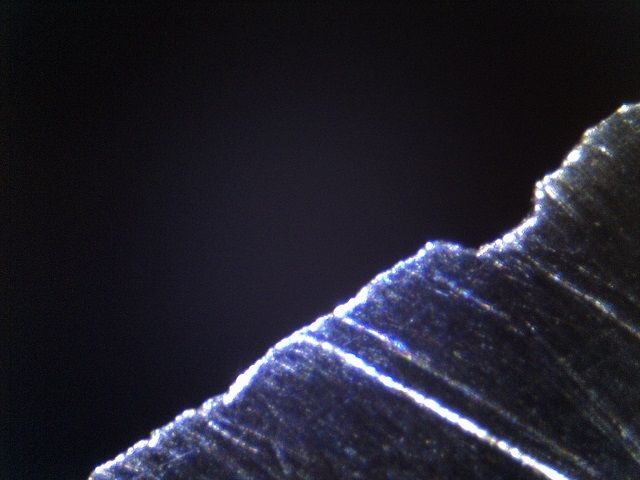

As the image on the right shows, there is some fracture, however it is limited to a depth of just being barely visible about :

If the knife was going to be used for that kind of use then the edge angle would need to be increase or the apex bevel increased in thickness beyond that of a micro-bevel to give it the necessary durability. But then it would have lower cutting ability and edge retention on lighter work. As this is more of a presentation knife than a raw-work knife, it will be left at the 5-6 dps edge bevel with the 15 dps micro-bevel.

The lock is the classic liner lock, developed by Michael Walker and it is one of the few weak points of the knife. Initially the lock engagement was so weak that it was instable and it would release with just light force on the spine of the knife. Now this isn't an uncommon issue with liner locks and it is one of the more controversial views on locks. One of the fundamental arguments on it was originally made, or at least popularized by knife maker A. T. Barr :

You don't want your blade to open except when you want it to. Always check for a good detent ball to blade tang contact. Open your liner lock normally and then close it very slowly. The blade *should* snap closed the last 1/16" or so.

Open your knife blade very slowly, until the lock engages. Do not snap it open. You want the tension of the liner lock to just snap to the tang of the knife. Then do two things. First turn the knife over, and using the palm of your hand try to close the blade. It should not close. Then strike the blade spine on the table. Not real hard, but it needs some pressure. It should not close.

This blade fails the first of A. T.'s checks as simple hand force on the spine will cause the lock to release. Now as A. T. Barr and Joe Talmadge would note, a lot of these problems can be fixed by hard inertial openings which cause the lock faces to wear a little and have better engagement. This usually can be checked by doing a hard opening and check if the lock engages securely. This was the case here and with a little use/wear the lock eventually became stable.

Aside from the initial issue with the lock engagement, the opening/closing and general action of the knife was solid. The detent kept the knife closed even to the point it is difficult (to impossible) to inertially open it, but once the detent contact is initially broken, the knife opens smoothly. The liner is also lightly jimped and the handle has a generous cutout which makes the release and close of the lock very easy/efficient.

Nominal composition of VG-10:

VG-10 is an interesting steel and unfortunately it is a Japanese steel and thus direct information on it isn't as accessible as many other steels which are very similar in class. However there are some very similar steels for which there is a lot of information. 19C27 for example is a simple steel from Sandvik and it is easy to find not only composition but micro-graphs and detailed hardening directions and even reasoning on design/composition and scope of use:

Sandvik 19C27 is Sandvik's most wear resistant knife steel grade and developed for abrasive applications. Sandvik 19C27 is the odd grade in the Sandvik knife steel portfolio because it's a coarse carbide grade, unlike the other Sandvik knife steel grades.

The coarse carbide grades excel at wear resistance but do not allow keen edge angles and have limited edge stability, due to the sacrifice of toughness related to the coarse microstructure.

Sandvik 19C27 is developed for industrial blades for cutting cardboard and tough fiber materials. The world class wear resistance is the main reason why this grade should be selected. Sandvik 19C27 is limited in corrosion resistance and we recommend surface coating on Sandvik 19C27 for knife applications to avoid corrosion issues.

Now as a point of clarification, estimating properties of one steel from another when many elements change is very difficult, however in this case it isn't impossible because there are many changes which both make the same type of influence and there are no direct contradictory influences :

A micro-graph of 19C27 is shown on the right compared to AEB-L. Note 19C27 has both a larger volume of carbides and much larger primary aggregates up to 15-20 microns in size. This is perfectly consistent with Sandvik's description of it being a coarse steel for cutting abrasive materials more so than retaining a fine cutting edge.

This steel thus isn't designed as a razor blade steel (such as 13C26, AEB-L, 12C27, or the non-stainless steels such as 50100-B, W1, etc.) but is designed for maintaining an aggressive slicing edge and to more strongly resist wear. Other steels in the same class are MBS-26, AUS-8, and 8Cr13MoV.

Now clarity has to be noted in any such statements because they are all relative, 19C27/MBS-26/VG-10 for example has a higher ability to hold a fine cutting edge vs an even higher carbide steel. As with all relative style rankings, the point of views or reference standards are critical.

Material properties aside, how to interpret the above? It is trivial to say that on paper the properties of a steel are X however how to translate to practical use in hand? Often times these differences, while real, are often very difficult to see due to all the random influences when knives are used by people. For example a recent comparison of VG-10 vs S30V on slicing hemp did show that S30V had a slight advantage over VG-10 at the same angle/grit finish 1 . Similar performance is seen comparing the Lum to a number of other knives slicing hemp 2 .

However in order to see these kinds of differences,

multiple runs had to be completed and averaged with the

same angle/grit finish and constraining the cutting to a controlled speed,

style of cut and statistical sampling of the material being cut.

If the comparison is not as controlled then those kind of small differences and even much larger ones can be difficult to impossible to spot 2 . Note the image on the right which shows a comparison of the Lum vs three other knives in three different steels :

While the comparison is strictly controlled in terms of edge angle, apex angle and grit finish, type and nature of cutting - the material used was not random sampled and thus due to that one factor alone it takes approximately ten repeated trials for the data to show there is any difference at all between any of the steels.

In short, VG-10 is similar to the following steels in nature :

and it is harder/strong and more wear resistant (but less corrosion resistant) than :

But it is softer/weaker and less corrosion resistant than steels such as:

One of the most immediate large differences in VG-10 if it has not been used before is that unlike steels such as 420HC, it generally requires a fairly fast/aggressive cutting stone in order to grind well. It is one of the steels that if it is the first time a stainless steel is used can produce that old chestnut that "stainless is hard to sharpen" as VG-10 is much harder to grind that the 1095, 52100 type steels.

In general, while it is possible to grind it with natural stones such as the common Arkansas stones, it generally is more efficient to use a more aggressive cutting stone such as a Fine India. However it isn't so hard to grind such as steels such as M2, ZDP-189, S90C etc. that it requires very fast cutting specialized stones such as the Sigma Power II stones (which are waterstones developed to cut HSS), or Diamond or CBN plates.

In regards to steeling, as it is has a fairly high carbide volume, it won't be as responsive to the kind of burnishing action that is obtained from using a butchers steel or even a smooth steel or slick. They can be used of course but the edge tends to weaken due to fatigue and can fracture likely to to carbide instability issues 4 .

In short, a very succinct description :

All in all this is the perfect everyday carry knife for anyone who may want something that looks distinctive and more aesthetically appealing than the norm.

There were some initial issues with the lock and in general the ergonomics are lacking for harder use. But there is no denying the obvious visual appeal (though subjective) and it is an excellent example of VG-10 in an efficient cutting design.

Comments can be emailed to cliffstamp@gmail.com or by posting to the following threads :

Most of the pictures in the above are in the PhotoBucket album.

1 : Micro-Bevel influence on edge retention slicing hemp (VG-10 and S30V)

2 : Edge retention slicing hemp, various steels, 15 dps MXF DMT microbevel

3 : DMT x-coarse edge retention on cardboard

4

: Edge retention with steeling (12C27 vs 3Cr13)

| Last updated : | 26/01/2015 |

| Originally written: | 28/08/2013 |