- SureFire delta

- Spyderco Paramilitary

- Spyderco Bob Lum

- Spyderco Bradley Air

This review consists of :

Knives :

This review consists of : |

|

The Air is meticulously manufactured from premium materials that literally allow it to live up to its name. Its handle is built on a foundation of full-length titanium liners that also support the structure of its Walker LinerLock mechanism. Skeletonized to reduce weight, the liners are covered with silver twill glass fiber laminate scales that provide a lustrous three-dimensional appearance and just enough texture for a secure grip. An open-back construction style further reduces the weight of the knife and allows for easy cleaning, while its unique internal stop-pin construction supports an exceptionally narrow, pocket-friendly profile.

The heart of the Air is its CPM M4 Wharncliffe-style blade. Combining a perfectly straight cutting edge with full-flat-ground bevels, it provides outstanding cutting performance for its size. A decorative swedge on the spine adds a visual accent to the design and provides a comfortable index-finger perch for scalpel-like control when cutting with the tip. Spyderco�s Trademark Round Hole nests comfortably in a scalloped recess in the handle when the blade is closed. More convenient and accessible than a traditional nail nick, it allows convenient opening with either one or two hands.

In the open position, the Air�s blade locks firmly via a LinerLock mechanism. To release the lock, two relief cutouts are provided in the opposite handle liner. One also serves as an access relief for the Round Hole, while the other, which is closer to the pivot pin, provides extra leverage for easy operation.

Unlike most Spyderco folding knives, the Air does not have a pocket clip. By design, it is a gentleman�s folding knife and is therefore intended to be carried inside the pocket.

The Air is a distinctive fusion of Gayle Bradley�s design talents and Spyderco�s tradition of innovation. The result is a new standard in gentleman�s pocket knives that offers both practical cutting performance and great pride of ownership.[/quote]

Maker Webpage : Bradley Air :

Specifications :

A quick web scan and some frequent comments :

and common very strong praise :

What would happen if you took the shape and weight of the Al Mar Ultralight and the cutting performance and opening hole of the Dragonfly and combined them in a single knife? You'd get the Spyderco Air.

I am not going to waste time here--this is a superior knife.

The only general common complaint is that the initial edge thickness of about 0.020" is a little more than what would be optimal for this blade and the general intended scope of work and it is common to regrind it to generate a more consistent profile :

When I first got it I liked the knife overall but thought it was too thick behind the edge and found blade finish a little rough. Since then I have thinned out the shoulder of the edge, so now the blade flows from the back to the edge in a slightly convex curve. The first halve centimeter from the edge is now just a little thicker than on an Opinel in the same area. I consider the blade grind on Opinels to be a benchmark of a thin, very well cutting, folder blade. I used an extra course DMT diamond stone for most of the shaping. It was then cleaned up with sandpaper. The edge was finished on an extra fine DMT stone. It how has a fine jet toothy edge that will easily cut phonebook paper, shave arm hair, as well as be grabby enough to bite into and cut plastic packaging material.

The only two common complaints, are the proud liners and the secondary lock access, but there are those that prefer those as well :

One of the features that I really loved about the original Spyderco Gayle Bradley were the proud liners and the Air has them too. It doesn't take away from the comfort of the handle at all but somehow gives the knife an extra air of quality. I'm not sure if there is a functional reason behind this aspect of the design, but it sure looks lovely. And this is where the Air really shines...being a darn lovely looking dress knife!

As a point of clarification, this Air was previously owned by Mike Gavac (gavko on YT) who :

In general concerns need to be taken with acid baths which hit the edge as there are reasons to be concerned with hydrogen embrittlement.

The knife was bought used so had a small amount of the usual scratches and minor wear from use. The only real issues which stand out in regards to finish/consistency are :

However on the last one, there is a design view in which that is intentional and not a negative, a point of preference only.

Note that the cutting as noted which follows is enhanced over the stock Air due to the transition bevel applied by Mike Gavac. Some numbers on 3/8" hemp :

On carving wood compared to the #1260 Mora :

As expected as the Air has a slightly higher edge angle and when light force is used the cutting is mainly influenced by the edge angle so it is a bit behind the Mora.

It was expected that the cutting performance would be much higher when heavy force was used as the primary grind thins out the edge however the handle of the Air isn't suitable for a heavy hammer grip and thus a lot of the force applied is not effectively used and thus it can at best have a slight advantage over the Mora.

As a very basic check on edge retention, through 500 slices through pine there was no

This is a low standard for edge retention and if a knife can not do it then it is simply a sign of a poor hardening or sharpening. It is a quick check however just to see there are no major problems.

Most knives can be pressed into use in the kitchen as in general many foods are often soft and easy to cut and if not a lot of work is done well basically any knives can to some extent make one piece of food into several. However the Air, aside from the fact it has a pivot, is next to an ideal small paring knife :

As described in the above the edge was reground

to close to true zero to improve its cutting performance, but even with the

as-boxed profile it isn't poor. However with a true-zero convex profile it is

able to compete in regards to cutting ability

with ideal blades such as the Herder paring knives.

For general use, as all paring knives, it suffers in the kitchen due to lack of length. However that is nothing more than attempting to press a paring knife into more utility knife applications. For much beyond light paring, even though it doesn't inherently cut as well due to a heavier grind/stock, something like the K10 Mehr/Spyderco collaboration is simple far more functional simply due to size/length.

However for practical purposes the Air is able to easily handle small tasks such as cutting up :

to make a sandwich, and the light weight and high cutting ability is easily appreciated.

For general utility, the very thin tip has its advantages, easily poking into plastics and enabling precise cuts and the very narrow blade also allows it to turn in cuts well. However the exact same features which in many ways are benefits also raise their own issues :

It quickly becomes obvious that for more rugged cutting then something like the Chicago or Pingo is more suitable as they are more rugged designs with more secure grips.

A couple of examples of tasks which demand a heavier ground blade are shown to the right :

These are in some cases heavy (ab)use but they are easily done with even fairly small/light knives that just have a slightly heavier profile such as :

There is of course the simple tradeoff that the much slimmer Air, while not being well suited for such work is a lot more efficient in lighter work so the choice just has to be made as to suitability for common use. A nice combination of carry is the Air and a small neck knife which is decently rugged like the Uddo Puukko (which is the knife in the sod picture) to allow a very capable and wide scope of work.

Ergonomics : the knife is very neutral and does not have any aspects which prevent grip versatility such as prominent guards or severe shape indexing. However as it is rather short and flat it doesn't work well in any heavy hammer or even sabre style grips. However for light sabre grips and side pinch grips it is comfortable and those are the grips for which it is mainly used. It is in fact so light in hand (not for nothing is it called the Air) that this itself enhances the comfort.

Security : the grip does has very low security :

However this is a knife made for light work in general and the light surface texture from the glass fibre based scales easily keeps it steady in hand for the work it does well.

Durability : the scale material is not only decently resistant to scratching it also hides scratches very well due to the pattern which makes anything other than major damage very difficult to see.

The Air has the standard Michael Walker liner lock, has full engagement and it secure under all the checks which are promoted by Joe Talmadge and A. T Barr :

It has a medium strength detent, strong enough to keep it secure, no issues with causing a stiff opening. The lock release has both the traditional side access and a novel top access as shown in the blow up image at the right. Opinions tend to be mixed on the utility, personally, only the traditional release is ever used.

The knife is clipless and doesn't come with a sheath so it is pocket carry standard, no keychain/fob hole either. It is in many ways a unique piece as Spyderco definitely popularized the folding clipit if they didn't outright invent it.

M4 is a high carbon, high speed steel. In the knife industry there was, and still is to a reduced extent, some promotion of it as having high toughness however such claims are often problematic due to the lack of reference points. The materials data, even in the most positive case as presented by the manufacturer show it to have lower toughness compared to tool steels such as A2 and is similar to high carbide stainless steels such as S30V, 1, 2, 3, 4, 5 . This is not surprising as it is a high carbon and thus high wear modification of M2.

As noted in the image to the right, it has a high carbide volume, but the carbide size is small (on the order of 2-3 micron) and thus given an optimized hardening it would be expected to hold a fine sharpness for an extended period of time, have little issues with carbide tear out and aside from gross impact concerns (chopping), the main issues would likely be with difficulty of grinding.

In regards to sharpening, the Air was indeed difficult to grind due to the high hardness and a volume fraction of very hard carbides. In fact many basic oil stones, and most natural stones, can fail to cut it. Waterstones such as a 3000/8000 from Henckels would fail to significantly cut the steel and have a very glass like feel even with a light slurry.

It is critical to ensure that the abrasive can cut the steel well or otherwise there is a high chance of the burnishg and ploughing vs cutting. When the abrasive start deforming the steel and just rubbing it not only fails to effectively shape the steel, it can leave it in a weak and brittle state. While it can be sharpened with most stones using various techniques (form a fast cutting slurry, ensure the stone is constantly surface recut) it was found in general to sharpen the Air efficiently it was necessary to use specialty stones such as the SPS-II waterstones, and diamond or CBN plates.

The knife came from the initial owner with a slimmed out profile

through use of the transition bevel, and

due to the more restricted scope of work

it was going to be used for, it was reduced even further to a close to

true-zero grind. It was ground down gradually on multiple stones, the bulk of

the work was done with a Bester 700 waterstone, with a soak and a lot of force

to generate a fast cutting slurry. The final profile left the

edge at 6-8 dps under 0.010" thick, above that was the primary grind angle.

The basic shape also leads to ease in

sharpening as it has a very straight edge with little/no belly.

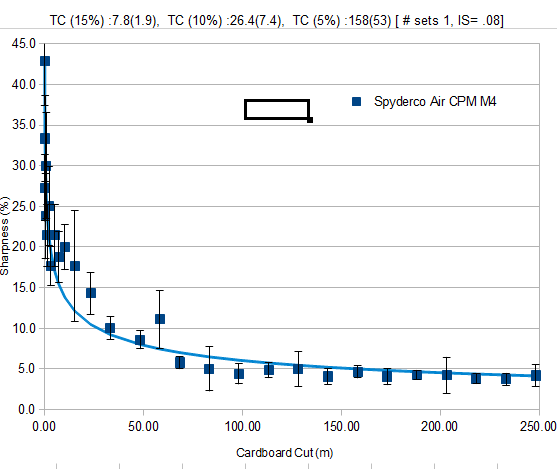

As for edge retention, there were some issues with edge retention initially however that could be due to the acid wash or it could just be random bias. In repeated sharpening with extended cardboard trials, it showed among the highest performance of blades seen 9 which is not surprising given the :

The last point is a bit of an interesting point as at some point as shown in the cardboard and hemp comparisons the carbide volume increasing starts lowering the edge retention which could be due to an issue with apex stability 10 .

As for corrosion resistance, M4 has a small amount of chromium which is dissolved in the steel in the soak to prevent diffusional phases in the quench and enhance the secondary hardening response. The same chromium however also makes it significantly more corrosion resistant over simple steels such as 1095 and L6. In general use with the Air, it needed much more care than stainless steels but no where near simple plain carbon steels. In the kitchen for example it was sufficient to just rinse and clean it on occasion to keep it free of rust. It was not necessary to use the two-cloth method common for example on Japanese White steel.

The Air is a solid mix of both aesthetics and performance from Spyderco :

Overall the Air was well worth the wait. For me this is a near perfect dress knife and is just exquisite as an object in its own right. Despite it's delicate appearance and light weight the Air feels as tough and sturdy as it's larger sibling and I'd say it's a must have for any Gayle Bradley fans.

The only real negative that could be argued is the initial edge thickness, but there is a personal preference there for cutting ability/edge retention over durability in accidental impacts.

Comments can be emailed to Please Use the Forum or by posting to the following thread :

1 : Crucible data sheet on M4

2 : Crucible data sheet on 3V

3 : Crucible data sheet on S35V

4 : ERASteel data sheet on M4

5 : Carpenter data sheet on M4

9 : Edge retention slicing cardboard, 15 DPS/600DMT microbevel

10 : Edge retention on slicing 3/8" hemp, 25 dps/6 micron DMT finish.

11 : Heat treatment effects on CPM-M4 tool steel performance as edged blade material

Most of the pictures in the above are in the PhotoBucket

album.

| Last updated : | |

| Originally written: | 19/05/2013 |