- specifications

- stock evaluations

- general work : food, wood, miscellaneous

- edge retention , ease of sharpening

- lock

- grip

- overview , comments and references

The review consists of :

|

|

The M16-14Z is made from AUS-4 stainless steel hardened to 55/57 HRC. It weighs 170 grams and is 0.135" thick with a sabre hollow grind which tapers to an edge 0.028" thick and chisel hollow ground at 20 degrees included, the one inch section of serrations are ground at the same profile. There is a very tiny bevel on the back, about 0.010" wide, likely from a buffer.

With the origional edge profile and new in box sharpness, the M16 cut 3/8 inch hemp with 15.5 (5) and 24.5 (5) lbs on a slice through two inches of blade and a push cut respectively. The serrated section (one inch) could make a slice in 12.5 (5) lbs.

The M16 has a fairly wide tip, 0.8" due to the geometric tanto profile which as a short taper of 0.725" ground at 5.3 degrees. On a 50 lbs push into a phonebook it sank to a depth of 165 (4) pages. On a hard stab is went to a depth of 519 (27)

As a paring knife the M16 was problematic due to the width and

thicker than optimal profiles. While it could readily peel potatos as this is

mainly just a function of sharpness, it had to slice off sections rather than

make a continuous peel, and it had problems removing eyes due to the broad tanto

point. Performance was also low to moderate on tasks like coring an apple or

cutting the rind off a melon. Such work is best done with a very narrow blade

like the Jess Horn. The M16 is however much

more effective than knives like the Fulcrum.

As a paring knife the M16 was problematic due to the width and

thicker than optimal profiles. While it could readily peel potatos as this is

mainly just a function of sharpness, it had to slice off sections rather than

make a continuous peel, and it had problems removing eyes due to the broad tanto

point. Performance was also low to moderate on tasks like coring an apple or

cutting the rind off a melon. Such work is best done with a very narrow blade

like the Jess Horn. The M16 is however much

more effective than knives like the Fulcrum.

| As a utility knife, it worked well for tasks which were more centered on pure sharpness such as slicing up green onions. It could also slice up onions readily, including the horizontal cuts necessary for fine dicing, but had control issues due to the greater cross section compared to optomized kitchen utility knife, but in general did well for a tactical type folder. On slicing thicker and more rigid vegetables such as potatos, it started to lag behind and a more optimal knife would quickly be desired and for a lot of fine dicing a dropped blade would make working to a cutting board much easier. |

|

|

| For working on meats, the M16 readily sliced through some strips of pork which just demands a high sharpness. It also worked well seperating some pork ribs easily slicing through the connective tissue and through the end caps of the bone. For thicker cuts of meat a long blade would be prefered and the tanto point is less than optimal as a smooth curve is easier to use. The tanto on the M16 however isn't as abrupt as those found on knives like the WB and thus is inbetwen that geometry and a drop/clip point in the flow of the belly. The serrations do lower performance on long slices as well but can come in handy making hard cuts such as slicing the heads off of large cod. |

|

|

As a bread knife, the M16 lacks the length to work efficiently

on large loaves of bread and thus multiple slices are necessary to make conplete

cuts, a knife like the Catcherman works very well

for such cutting. However the serrations on the M16

readily slice into even the hardest

and crustiest of breads and will cut fresh breads without squashing.

As a bread knife, the M16 lacks the length to work efficiently

on large loaves of bread and thus multiple slices are necessary to make conplete

cuts, a knife like the Catcherman works very well

for such cutting. However the serrations on the M16

readily slice into even the hardest

and crustiest of breads and will cut fresh breads without squashing.

| Carving wood, the M16 make 100 slices into a piece of clear pine lumber. The edge sank in readily due to the acute profile and the grip was decently comfortable. However clear pine is very soft and easy to cut. The same amount of work was done on a piece of birch (tree branch). The inside of the handle slabs on the M16 were found to be a little sharp, but above average. The cutting is best done with the plain edge but this is so far infront of the grip that there is a large leverage disadvantage. This can be compensated for by running the index finger in the choil, but this generates discomfort against the pinky which is no longer in the curved section of the grip and now isn't as well supported. More cutting was performed on 3/8" plywood. The M16 cut well and had no trouble cutting the hard wood including sectioning through a couple of knots. There was no visible damage to the edge, which also showed no chipping under 10 times magnification This wood working did blunt the edge down past the ability to slice paper, so it was resharpened, still having the origional hollow ground edge profile. |

|

| |

|

| Removing bark to gather the heavy pitch, the M16 worked well cutting around the sap on thick barks, using a hammer grip cutting with the point. The serrations work well making the vertical cuts at the end as they cut through the bark more effectively than the plain edge. It is more efficient to cut well away from the sap both to not waste any and to try to keep it away from knife as much as possible. The M16's point is then worked under the cuts in the bark, to pry it up, a bark spud can be carved here to make this process a little easier. The bark can be processed to make glue, the easiest way to get it off the bark is to boil it and remove the sap as it seperates. To the sap add animal scat, ash, wax or tallow to make pitch glue. The glue can be used as a water sealant as well, and it burns very well so makes excellent torches and tinder. |

|

| |

|

With the initial edge profile and sharpness, the M16-14Z cut in well on thick

cardboard, but the edge retention was low, breaking down a box, after just a few

cuts were made, totaling a few meters, the edge was essentially gone and the

blade would slip out of the cuts :

It was resharpened, the origional hollow ground profile still persisted as it

was fairly deep.

With the initial edge profile and sharpness, the M16-14Z cut in well on thick

cardboard, but the edge retention was low, breaking down a box, after just a few

cuts were made, totaling a few meters, the edge was essentially gone and the

blade would slip out of the cuts :

It was resharpened, the origional hollow ground profile still persisted as it

was fairly deep.

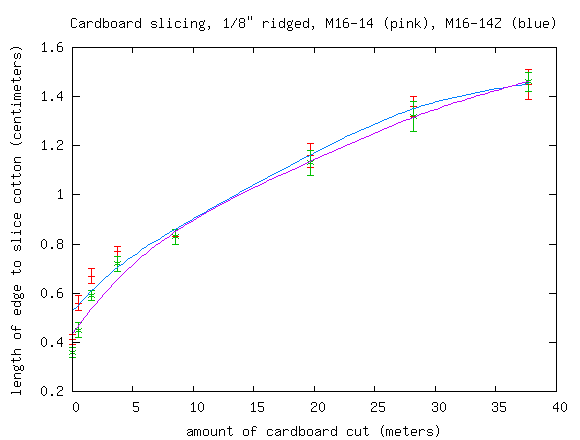

On cardboard, the first run comparing the edge retention on 1/8" ridged cardboard of the AUS-4 (55/57 HRC) M16-14Z to the AUS-8 (56/58) HRC, M16-14. The knives were left with a very coarse finish, 90 grit AO, sharpened at 15.0 (5) degrees included. The blades would shave, push cut newsprint at about half an inch from the point of tension, and readily slice paper towel. The sharpness was checked during the cutting by slicing light cotton under 200 grams of tension as well as checking the ability to cut newsprint and shave. The cuts were made through 30 centimeter sections of cardboard with an average time of 2-3 seconds per cut. The average result of four runs :

The curves are weighted cubic splines, essentially just a smooth curve which tries to run between the points with no radical behavior. Note the two distinct regions of behavior, the initial rather sharp decline in performance up to about five meters and then the leveling off in rate of blunting. There is a bit of scatter early which is to be expected since a small amount of cardboard is cut, but after a hundred or so cuts with each blade there is no significant difference in behavior. At the end of the cutting the blades could still scrape shave a little, and push cut newsprint on an angle and were still cutting the cardboard very well. The numbers :

| Knife | Cardboard | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.0 | 0.5 | 1.6 | 3.8 | 8.5 | 19.7 | 28.8 | 37.7 | |

| M16-14Z | 41 (2) | 56 (3) | 67 (3) | 77 (2) | 85 (3) | 116 (5) | 136 (4) | 145 (6) |

| M16-14 | 36 (2) | 45 (3) | 59 (3) | 72 (2) | 83 (3) | 113 (5) | 132 (4) | 146 (6) |

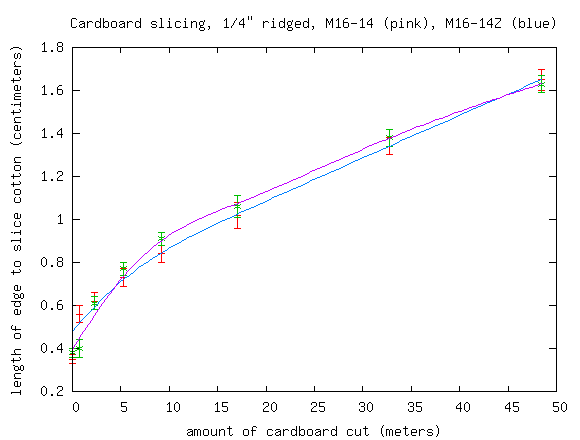

More cardboard cutting was repeated on thicker cardboard to more extensive blunting and the behavior was consistent with the knives both still staying very sharp for a long period of time:

There is again no difference seen between the two blades. At the end of this more extensive round neither blade could shave, but were still slicing cardboard cleanly and readily slicing newsprint. The numbers (an average of three runs) :

| Knife | Cardboard | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.0 | 0.8 | 2.3 | 5.3 | 9.2 | 17.0 | 32.2 | 48.4 | |

| M16-14Z | 35 (2) | 56 (4) | 62 (4) | 73 (4) | 84 (4) | 102 (6) | 134 (4) | 165 (5) |

| M16-14 | 38 (2) | 40 (4) | 61 (3) | 77 (3) | 91 (3) | 106 (5) | 138 (4) | 163 (4) |

Here again there is no significant difference in behavior between the two blades. What is interesting is that the thicker cardboard didn't seem to signficantly increase the rate of dulling, likely due to the fact that the edge retention of the really coarse grit was so high that even a signficant percentage increase on the blunting rate would not readily been seen. The M16 in AUS-4A was also compared to a Point Guard in 420J2 and a Temperance in VG-10 slicing cardboard with an aggressive finish. The AUS-4A blade inbetween 420J2 and VG-10.

The initial edge is hollow ground which raises the ease of sharpening because the abrasive just hits the top and very final part of the edge and thus it is sharpened very quickly, the edge is also ground evenly which further raises ease of sharpening. The biggest problems are that the steel tends to be difficult to form a crisp edge as tends to be common for soft stainless, and the chisel grind makes this difficult assuming the back is honed flat and not beveled to make the edge v-ground.

The M16-14Z has a liner lock with the LAWKs secondary locking mechanism. The liner responded to impacts on the spine well, no issues with releases, however during the cutting of the sap in the above, the M16-14Z was hit on the flipped to knock small pieces of frozen sap out from around the pivot and this induced the liner to travel all across the tang and moved off of it as there is a gap between the scale and the blade tang.

The grip on the M16 is solid in most respects, all the holes are points of contamination, but other than that there are no real points of contention. The inside of the handle scales could be a bit more rounded, but they are better than most.

The M16 had relatively high cutting ability for a tactical folder and an above average grip. The edge retention for long term slicing was low when compared to high carbide steels such as VG-10, however with an optimal edge angle and grit, the M16 could still retain the ability to keep a high sharpness for an extended period of time. The only significant downside was the inability of the lock to withstand even light impacts on the spine.

Comments can be emailed to cliffstamp@[REMOVE]cutleryscience.com and posted to :

More information on the M16 can be seen on the CRK&T website.

| Last updated : | 01 : 10 : 2006 |

| Originally written: | 01 : 05 : 2006 |