The head on the Wetterling hatchet [img] is hand forged out of Swedish steel and the edge tempered to 57-58 RC. The head is left in the as-forged state except for the edge which has been polished.

The head weighs 1 1/4" lbs, the total weight of the hatchet is 600 g, similar to a large bowie. The overall length is 12.25", the distance from the center of my grip to the center of the head is 7.75" ( 8.75" on the Gransfors Bruks Wildlife Hatchet). The head is centered on the handle, wedged in place and secured with a metal locking ring. The handle is hickory, vertical grain and has a slick finish that needs to be removed.

The bit of the axe is a little thick, checking the thickness against the Wildlife hatcher from Gransfors Bruks, the Bruks axe is significantly thinner consistently : 0.440 (0.365), 0.295 (0.232), 0.205 (0.172). However the primary edge grind on the Wetterling axe is thinner than that of the Bruks hatchet. The Bruks hatchet hits 0.25" in thickness at 1.35" back from the edge, on the Wetterling axe this thickness is hit further back at 1.50".

The Wetterling has a secondary edge bevel about one millimeter wide which varies from about 21 to 30 degrees per side. The edge bevel is also wider on the heel of the bit than the toe. A very light burr can also be felt along the edge.

The hatchet it will push cut light thread taking between 180 and 440 g. Cutting 1/4" poly under a 1000 g load requires between 2.75 to 4.75 cm. The heel of the bit is much sharper than the toe. For reference a sharp blade will cut the thread at about 100 g and slice the poly under that load in under one centimeter. The Gransfors Bruks axes come at that level of sharpness, very high.

The handle design is very solid. The top of the handle in the grip region should be an "S" shape. It should curve up to fill out the center of the palm and then hollow out to give a smooth transition across the edge of the hand. The bottom of the handle in this region should have a very pronounced hollow which is used both for security as well as for driving against for very powerful snap cuts. This is exactly how the handle has been shaped. The only negative aspect is that the end knob has extremely square edges which should have all been rounded off.

The hatchet also comes with a small pamphlet, a short version of the "Axe Book" that Gransfors Bruks produces. After reading it is not 100% if this is the "Campers Axe", the head weight does matches the specs as does the length, however the poll is polished and curved for use as a flay poll such as found on the hunters axes, yet the corners are are left squarish which would make skinning difficult.

The quality of the forging is far below that seen on the Gransfors Bruks Wildlife Hatchet. The Wetterling hatchet shows numerous fold lines throughout the head and basically it is not well shaped. For example the tip of the head should be flat, however it is not, there is actually a dip present, more of a wave actually. Most of the transitions are also not very smooth but are abrupt and angular and there has been shaping done by a grinder along the underside of the head. The lugs are also misshapen.

Most of these aspects are just cosmetic

There was a fair amount of rust of the head when it arrived. With a finish this rough you really want to ship the blade with a good coat of oil or wax. This isn't a major problem, and it can easily be cleaned, but when you warn about letting your axe rust with the instructions that come with the axe, and it arrives rusty - well that doesn't make a lot of sense.

The edge also doesn't have the right curvature. The edge should sweep out in a nice circular arc. The profile on this hatchet is kind of square, not as flat as you would see on a carpenters hatchet but not as round as you want for fresh wood hatchet.

There is also a problem with the head alignment. Sighting down the bit along the handle the edge skews to the left. This lowers performance as when chopping the driving is along the center of the handle, and therefore for maximum performance the edge should be presented to the wood in line with this thrust vector which means the edge should split the end knob of the handle.

When this isn't the case the penetration will be lowered because the edge will not receive 100% of the thrust as a drive but a portion of it will be wasted fighting the skew produced in the cut thus the cuts will not be as deep. The second problem is that since the axe goes off line in the cut it is much harder to get the chops to follow each other smoothly and the probability for glances is increased.

However on a small hatchet a lot of the power can come from the drive after the axe hits the wood and thus the skew isn't as much as a problem as on a felling axe. It also isn't bad enough for glances to be problem. A few thousand chops with the Wettering and glances are far and few in between.

This problem can be caused by misalignment between the head and the handle, a skewed handle, or a skew in the head. The latter is the most serious as its the only one you can't easily fix. This is the problem both of the small axes have. On a rather ironic note, you don't find this problem in cheap cast heads because they are very uniform because of the means by which they are made. Just consider hand forging a head and making sure that the edge of the axe is perfectly vertical and bisects the poll perfectly, far from trivial. The cheap axes often have skew in the head/handle attachment however.

The Wildlife hatchet also has a problem with head / handle alignment in the same manner.

Both of these axes, Wetterling and Gransfors Bruks are head centered balance which means if you hang them upside down they will stabilize with the head perfectly perpendicular to the handle. An axe balanced in this way (all double bit axes are), will generate less torque on the hand when in use and thus produce a much lower fatigue rate and higher precision, which in turn also lowers fatigue by simply reducing the amount of work being done thus the fatigue rate is doubly reduced.

Before any cutting the edge was full sharpened to a high polish. It sharpened easily though as the edge was well formed just a little unfinished. The handle was also sanded through the throat to improve the grip.

A lot of time was spent with the Wetterling and the Wildlife hatchet chopping with full powered swings from the shoulder with hard wrist snaps. The back or hips were rarely used as the off hand was on the wood holding it in place. Though infrequently heavier chops were used to clear out knots, and examine edge durability from a worse case scenario. The cutting was usually done when fresh with little or no fatigue. There were some runs with heavy fatigue to see if there was any difference in the performance as well to see if the grip was effected any differently (it wasn't). Along the lines of the latter a few runs were performed using sweat as well as a lubricant (Deep Woods Off) on the hand to check control (poor in both cases).

The wood chopped up was mostly Fir, harder than average as it was in a low light area which contained a lot of dead wood which was what was being cleaned out. The occasional piece of Black Spruce was used on occasion to check edge durability. The wood ranged from about 2.5 to 5.5 inches in diameter and about 15 to 35 feet long. Under 2.5" as then the hatchets could pretty much chop right through the sticks.

The Wetterling hatchet bit well into the first piece of wood. Using just light wrist action it easily went in about 1/2" or so, in the same class as the Gransfors Bruks Wildlife hatchet. Overall it sank in deep and did not wedge excessively. It stayed with the Bruks hatchet on all the wood and was never outclassed.

However there were a few problems with the nature of the cuts. For maximum comfort and thus productivity, the edge should enter smoothly and continue throughout the wood, this gives the minimum amount of shock which is good for both blade and user. The release of the blade out of the wood should also be smooth as to reduce fatigue and allow the chopping to be done at a fluid pace. The Wetterling axe had a few problems in these regards.

The face of the bit is square, much like a Carpenters hatchet, this means that the impact onto the wood is not as smooth as it should be and the penetration is lowered, and the ends are far too sharp and will bind excessively on partial cuts. The thinner primary grind on the Wetterling also made it bind just a little more than the Bruks, but this was just significant enough to be noticeable, it was not a functional problem.

Getting specific about the chopping performance the Wetterling axe ranked at 93 +/- 3 as compared to the Bruks Hatchet which is the baseline at 100. This is very strong performance and basically means that you would need to be closely counting chops to see which one is higher.

Periodically while chopping some of the larger wood chips would be carved with both axes. The Wetterling axe was not in the same class as the Bruks in this regard. This is due to the obtuse nature of the additional edge bevel on the Wetterling axe, 20 to 30 degrees, which is about twice that of the edge on the Bruks axe. The slightly more acute forming bevel would raise its relative performance slightly but not nearly enough to compensate for the overly thick edge bevel.

After the chopping sessions the edges were examined by eye and under a 10x scope. No damage was visible to either axe. Some light cutting tests, on paper and such showed both to be similar.

It was immediately obvious that the sheared off handle design on the Wetterling axe is a problem. If the grip relaxed a little during a chop it would slip down over the butt and then the sharp edge would come in contact with the palm and the small contact area would produce rather high pressures and thus discomfort. In contrast the handle on the Bruks hatchet has a full formed butt which is comfortable even when center hand gripped.

There is a large difference in regards to the quality of the sheaths in the two hatchets. The Wetterling comes with a belt loop, which is a very nice feature that the Bruks axe lacks, however the leather of the Wetterling sheath is poor. The Bruks leather is supple and pretty much looks the same as it did when it was bought years ago. However the Wetterling leather is quite stiff and acts more like cardboard than thick leather. The belt loop later ripped off as the sheath was being removed from my belt. The sheath was then torn into pieces by hand with little effort.

As the hatchet had some problems which could be addressed without much work, it was so modified and the performance enhancement evaluated.

Using a file the additional bevel was removed producing a smooth convex taper, this took a few minutes. A 1000 grit waterstone smoothed out the bevel which was polished with a 4000 grit waterstone and a chromium oxided loaded loaded strop for a fine shaving finish. The whole process was about 10-15 minutes.

On some whittling and the Wetterling axe showed a great improvement in its relative cutting ability. Whittling points on a one inch hardwood dowel, the Wetterling's the median performance was 18.6 +/- 1.1 cuts. The Gransfors Bruks is ~15. For comparison to a decent knife, the Cold Steel large drop point Twistmaster does the same thing in 12.2 +/- 0.8 cuts. The difference is influenced a little by the thicker edge on the axe, more importantly the axe is at a large leverage disadvantage because of the length of the head.

To remove the effect of the grip and focus on the edge profiles influence on performance, 3/8" poly was cut with a straight vertical push cut. The Wetterling hatchet required 41 +/- 2 lbs to make a complete cut and the Twistmaster came in a just a little bit lower, 37 +/- 1 lbs. Thus the hatchet is much closer in performance, which is expected given the edge angles are within a few degrees of each other. The Wetterling has a final edge bevel about 14 degrees. The Twistmaster has the same final edge angle, but the curvature and lower primary bevel will also increase the performance.

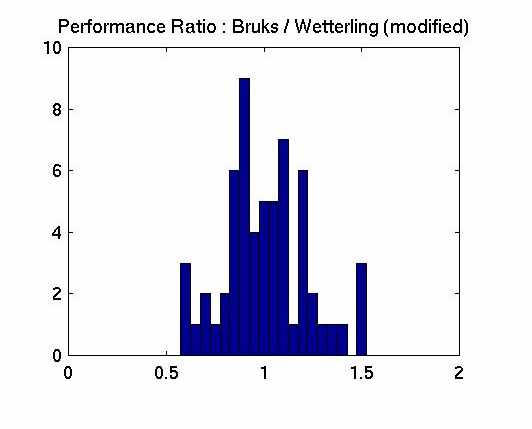

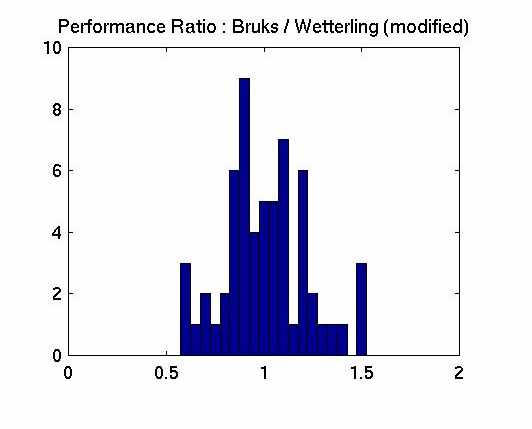

With the modified edge bevel it was readily obvious that the Wetterling now suffered no penetration impairment as compared to the Bruks axe. There is far more variance induced in the comparison by the wood and the technique used. If you are interested in some statistics, here is a histogram showing the performance ratio over 60 sections of wood cut :

The rank clusters strongly around one showing equal performance. The median of the ratio was exactly one with a standard deviation of 3%, thus the performance was very consistent.

During the chopping, again a decent number of knots were cut and neither axe showed any edge damage. Removing the secondary bevel on the Wetterling thus induced no functional durability loss for wood working. However for general utility work (sodding and heavy utility like cutting nails) the secondary bevel might be of benefit.

Initially there were some durability problems with the Bruks hatchet as noted in its review, however after adding a slight bit more sweep to the edge (two degrees) and working a lot on technique, the edge has held up fine through over 1000 pieces of wood.

After using these axes for awhile, the Wetterling was heavily modified to examine the influence performance :

Doing some more chopping, the penetration had not increased significantly and it tended to wedge more. The original profile was overall much better. note however that wood type has a large influence on the performance of a specific geometry.

The Wetterling products are significantly cheaper than the Bruks versions. Specifically ~$30 vs ~$55 for the smallest hatchets and ~$45 vs ~$65 for the limbing/forest axes. The extra money you spend on the Bruks versions does seem to be well spend as there are a number of differences, like an edge fully sharp right out of the box, as well as edge geometry issues, more secure head/handle attachment [the locking ring on the Wetterling fell out after extended use, the Bruks metal wedge is till after much more use], better sheath etc. . However for its cost the Wetterling is in a cost bracket that is not that much above general hardware store fare and it is a league above them in terms of performance. Its biggest failing is that it has to compete with the Bruks line which is a product that gives outstanding performance for the dollar.

Comments can be sent to : cliffstamp[REMOVE]@cutleryscience.com or by posting in the following thread on Bladeforums :

| Last updated : | 01 : 10 : 2006 |

| Originally written: | 10 : 03 : 2001 |