This review consists of :

The Vagabond was a fairly unique fixed blade from Spyderco which used an integral blade guard to replace a sheath and in some ways blend the ease of carrying a folder with the durability of a fixed blade.

The Spyderco Vagabond is designed for the wanderer. If you backpack, camp or picnic, chances are you've at some point needed a lightweight fixed-blade. The strong point of a fixed-blade knife is that they are manufactured from a single piece of steel with no folding parts to fail or break- ideal for use outdoors. A fixed-blade's weak point is they require a separate carry sheath for safe transport. The Vagabond's unique plastic sheath is made from part of the underside of the handle. A plastic cover pivots out/upward, snapping-over and safely covering the cutting edge eliminating the need for a bulky carrying sheath.

Sized to toss in a backpack or picnic basket, the FB12 is 7-7/8 inches (200mm) long tip to toe. Its blade is 3-1/8 inches (79mm) of AUS-6 stainless steel honed in a PlainEdge configuration, then ground-flat on both sides creating a powerful high-performance edge. The FRN handle is injection molded in a series of valleys and expansions providing ergonomic purchase to wrap your hand around. It comes covered with a slip-free Bi-Directional Texture pattern that latches onto your palm keeping the hand and handle connected even when wet or cold. A generously sized >lanyard hole allows a cord or thong to be strung through the handle for security around water, in deep brush or attaching the knife to a pack, basket or duffle.

Vagabond :

Push cutting 3/8" hemp required 17.7 (1.8) lbs through the tip, with 13.7 (8) lbs on a two inch draw, showing high aggression in spite of the very high polish, and thus having a complete sharpness profile. Pointing sections of hardwood dowel the Vagabond could form a one inch tip in 6.2 (1.1) cuts.

The point on the Vagabond is slim and acute and with a 50 lbs push sank 238 (10) pages into a phone book and with a hard vertical stab penetrated 888 +/- 21 pages. The penetration on the phonebook was extreme, mainly due to the very secure handle which allowed maximum transfer of power to the point as little was wasted in any slippage however there were issues with discomfort.

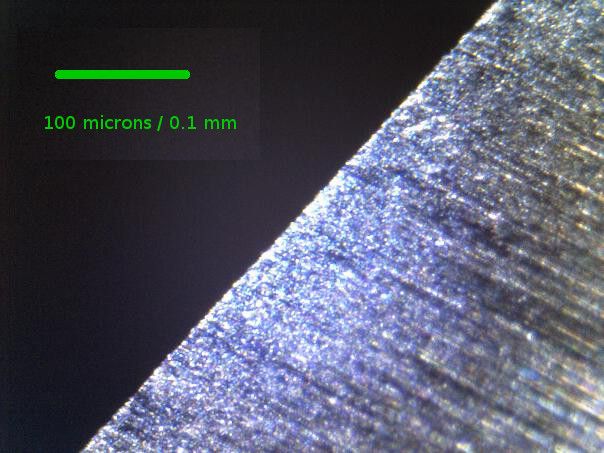

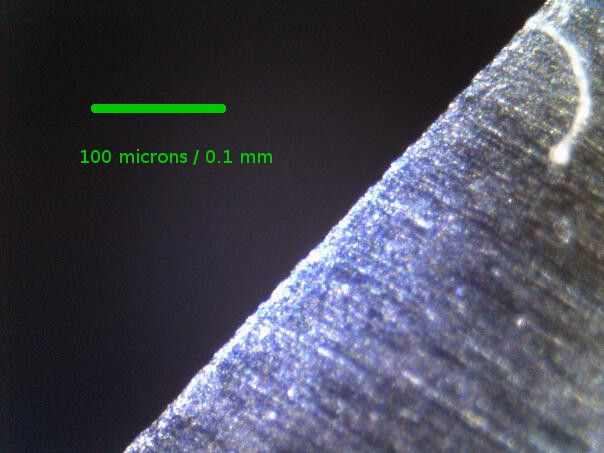

Given the fairly robust as-boxed edge grind and the high toughness and high grindability steel it excels in very demanding work such as cutting sods. The knife dulls as expected given the constant contacts off of dirt and even rock, however as shown in the image on the right it doesn't chip or in general even suffer excessive damage by deformation. This high durability is a combination of the fairly robust edge profile :

Combined with a very tough/durable steel. As a semi-quantitative check on edge retention and durability, ten sections of sod were removed, all approximately one foot by one foot and the number of slices were :

In short, while there is a decrease in cutting ability, it is small as sod cutting isn't very sensitive to sharpness and it would not be easy to even tell the first sod cut from the last in terms of general cutting ability. Reshapening was fairly simple given the low damage and high grindability. It only took 150 passes per side with 100-150 psi of pressure on a fine aluminum oxide stone, similar to a Fine India.

As a point of comparison in edge retention in push cutting with a high polish, the Vagabond was used to cut pine until it lost the ability to shave. This is a qualitative measurement so the precision is fairly low and it is essentially to do a few trials to establish a range.

The knife was used with the initial edge configuration and an apex bevel was set with the Fine Spyderco rod. The sharpness was checked every 250 cuts initially and then every 50 cuts once the sharpness got close to being fully lost. After a number of trials the average result and standard error were :

The apex suffered wear, however no significant deformation or fracture was noted and the sharpness could be restored by simply applying again the micro-bevel. This could be repeated several times before the apex bevel became so large that it was inefficient to keep setting it and then the edge bevel would have to be reset. This typically only takes 25-50 pps with a decent cutting coarse stone such as the #300 Suehiro Ryu.

Now there are a couple of immediate observations, first is that ~1000 cuts into pine before the knife even loses shaving sharpness indicates a decent level of edge retention. This is especially true when it can be reset back to the original performance by just a few passes on the Spyderco Fine rods and the process repeated. This means that it is in the neighborhood of 5000 to 10, 000 cuts before a more aggressive stone like the Ryu would have to be used which is a decent amount of work.

However, beyond that can a more quantitative comparison be made? A large number of knives in various steels were used. All knives followed the same method, the result from least to best :

In short, there was no significant pattern noted in regards to steel. There is simply too much random variation in natural woods. Interestingly enough the Vagabond had the highest performance but the random scatter was so high it could not be considered to be statistically significant. If the wood was cut with random sampling then a more precise ranking could be obtained however that does show that on some level that the edge retention of the Vagabond in AUS-6 is obviously functional given the lengths that have to be used to show the difference vs other knives in various other steels.

The Vagabond is made from AUS-6 which is a low carbide stainless steel, it has moderate hardness and is therefore very easy to grind. It also sharpens easily and tends to not have any issues with burr formation.

Note the images on the right showing the edge from a :

and then an apex bevel from a :

Even with the low grit waterstone, the edge forms cleanly. This was done using plateau sharpening where the apex is deliberately kept from over grinding to allow ease of setting the apex-bevel without having to deal with a burr.

The ease of grindability also means it works well even on natural stones due to the lack of the ultra-hard alloy carbides (Vanadium, Tungsten and Niobium).

The handle of the Vagabond is one of the strong points :

It fills the hand well and is secure in hard cutting with no chance of slipping, also enhanced by the very aggressive checking. Even on dirty work such as skinning back sods and in using gloves, the security of the grip is very high. Similar in the kitchen working on greasy foods and around fats and oils.

However the checking is fairly sharp and it could be found to be abrasive to the point of being uncomfortable. This is somewhat subjective as all grip ergonomics are influence by specific hand shapes/sizes but as a general rule, the grip was found to be far less hot spotting than common issues with folders with lack of chamfering and squarish pocket clips.

The Vagabond is a bit awkward to carry in the pocket of normal pants, but is easily dropped in a larger coat pocket or in a pack or even tool box. The blade guard for the Vagabond is easily released one handed, however is fairly difficult to engage back on the blade without two handed used. Once on the blade however it is secure and will not come off even with drops on to concrete from waist height.

As an extreme test, the Vagabond was dropped in a pillow case and jerked around for ten minutes to see if the guard could be released. Upon examination it was found that the guard had opened slightly and there was some fabric in between the blade and the guard. Note however that the extreme accelerations reached by the Vagabond in this test are a good deal higher than anything present on a person carrying it in any but fairly extreme situations and even then the guard could not be fully opened.

However this is one of the main concerns that many individuals had with the Vagabond, the potential for accidental opening and the danger it carried. This can be alleviated somewhat by simply putting an elastic band around the integral guard when it is packed away for extended periods.

The Vagabond is well suited to a tool box knife. It has a tough steel which is very corrosion resistant, a point slim and acute enough for utility cutting and proding, plus a decent blade thickness to afford some leverage for heavier work. The steel is also easily machined so repairing edge damage from abusive utility cutting required minimal time. It also works well as a utility blade to carry in the truck of the car for emergencies or better yet in the glovebox.

Comments can be emailed to cliffstamp@gmail.com or by posting to:

Pictures are in the PhotoBucket Album for the Vagabond.

| Last updated : | 11/05/2015 |

| Originally written: | 04 : 04 : 2005 |