This review consists of :

|

This review consists of : |

|

The TASK is an extremely coarse stone, so coarse in fact that it makes even most regular coarse stones look much finer in comparison. Note how the TASK has a grit size of approximately twice the size of the SPS-II 240X stone. This grit rating is so low that it isn't a commonly used stone for knife work due to the extreme nature of the abrasion from such large a grit.

Now this isn't actually intended to be used to sharpen knives. It is promoted as a garden stone and is intended to be used to sharpen tools such as hoes which usually are just ground to a very basic edge to cut through roots and similar. This stone has a number of features which make is very suitable for such use :

These properties allow the stone to cut quickly, it doesn't need to be soaked and it is easily flushed with water to remove any rust or dirt from working on the garden tools. However there are a few stones actually used to sharpen knives and other tools which have similar grit levels :

The Sigma Power 120 is a very specialized stone, as described from Tools from Japan :

Useful for gross metal removal to correct damage to blade edges or as a stone to restore the clogged surface of finer stones, this stone is unique due to it being so hard and so coarse.

The TASK, while not having the same pedigree :

The question then is can it actually be used to sharpen knives, and if so in what manner / function is it a useful choice?

The TASK produces a very coarse finish, part of the reason is obvious - it is a very coarse grit, ~100 microns. However the other part is the way it produces a slurry through the breakdown in grit. It has a very soft bond and sheds abrasive rapidly under even minimal pressure. As an extreme contrast, compare what happens, or what is produced, when two very similar grit stones are used to do a little grinding and then the slurry is flushed off and dried out on some paper :

The Shapton produces a very fine slurry consisting of :

This forms a fairly fine paste and so produces a finish well above

its grit size due to the random nature of all the fine particles moving around

during the grinding and how the smaller particles "buffer" the larger grit.

In comparison the TASK sheds large chunks of abrasive often full size

and so it produces an extreme harsh finish pretty much undiluted from the ~100

micron grit size

1 .

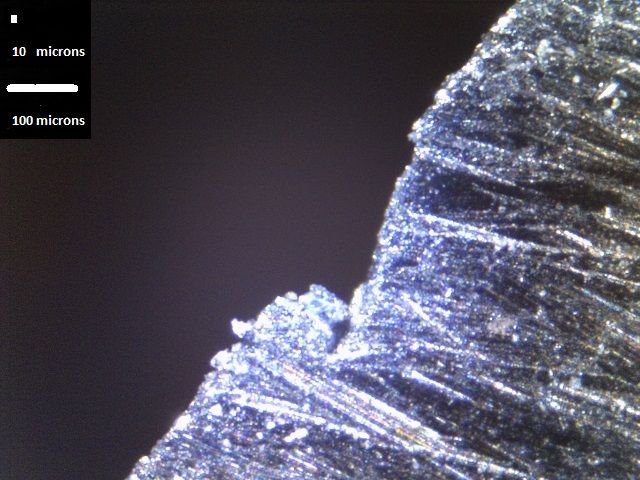

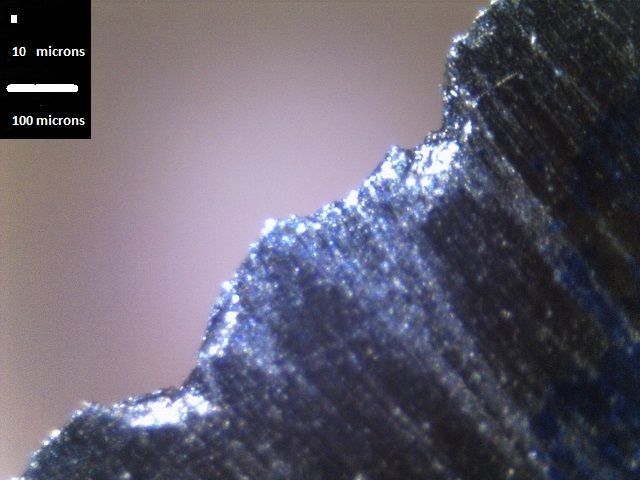

The clearest example of the very rough finish that is normally produced can be seen by looking at the edge under mild magnification. The Maxamet knives to the right were apexed with the TASK under fairly low force (approximately a pound, < 5 psi) and still produced very large pieces knocked out of the apex. In that in one case there is a clear case of fracture which extends beyond the apex and propagates up into the edge itself which could also lead to chipping in use continuing if it isn't ground out.

There is a pretty big downside to that aggressive grinding as it will take a fair amount of work with higher grits to remove all of that fracture. In the more extreme cases up to ~0.1 mm of steel has to be removed, that means in just 10 sharpening sessions a full mm of blade width would be lost. This is a rapid loss of steel and thus care has to be taken in using such an extremely aggressive stone. Normally such stones are only used when either :

However if an actual aggressive edge is desired for long lasting edge retention on a slice then the TASK can actually give very high performance for draw cutting on ropes and cardboard 2 .

It is possible however to use the TASK to apex the edge on a knife and not have it have significant damage. The basic method :

In short, the main method is to use the slurry to fill in the porous structure of the stone and mask/reduce the effective grit size. Using plateau sharpening complements this method by stopping just before the blade is over ground and leaving a small amount of the apex ( < 20 microns) unground.

However unless a challenge is wanted in grinding, a more sensible technique is to stop when the scratches start approaching the apex and then switch to a finer stone, though still coarse (Suehiro 'Chemical' for example) to finish the grinding.

The downside of the TASK stone is also in some respects its main benefit - the very weak bond strength. As the bond strength on the TASK is so low it sheds grit under very low pressure ( < 5 PSI). This has a number of benefits as it cuts very fast with low force, however it also means the upper limit of cutting speed is reduced because very large forces don't produce a corresponding increase in cutting speed as the abrasive is just shed vs cutting deeper. Plus the abrasive starts getting crushed as well.

At times very high pressures can be useful such as removing damaged and uneven grinds in a hurry. The chisel at the right shows large chips and an uneven attempt at sharpening. Using the coarse side of the Norton Economy which is also an xx-coarse silicon carbide stone but has a much higher bond strength then all of this damage was removed in just 500 passes. In order to achieve that speed of grinding the chips were removed by applying 250 to 350 psi and then 125 to 250 psi on the main bevel. This kind of pressure would actually just cut right into the TASK and carve it up like soapstone and thus if it was used it would not be able to match the cutting speed of the Norton on that particular task.

However the opposite happens when trying to thin out the primary grind on a knife. As the contact area is much larger it can be very difficult to get the pressure above 10 to 20 PSI and at the lower pressures the TASK will cut as fast or faster than the Norton and since it releases abrasive under those pressures and the Norton will not then it will continue to cut at that speed while the Norton will wear and slow down in extended use.

The TASK is a very inexpensive and basic stone, and it is designed and intended to be used on garden tools, hence the name. These tools are commonly made from mid carbon steels, often pure carbon steels and are very easy to cut/grind. It might be conclude that the use of the TASK is restricted to such steels but ironically it is best kept to be used on the exact opposite of those types of steels when used on knives.

In knives for steels which are very easy to cut/grind then a stone such as the Norton Economy is a much better choice as it can take much higher pressure with excessive grit shedding and will stay flat and require very little maintenance after extended use. However on very hard to grind steels the abrasive in the Norton will wear, it will stop cutting but the TASK will release abrasive and thus it always presents sharp abrasive and will keep cutting .

The TASK is very porous and it will saturate immediately when submerged. It can be used dry and it will load, and the cutting speed will diminish and the finish will increase (get finer). The more water is use the more rapid the stone will break down and the faster it will cut.

As the TASK has an extreme weak bond (it appears to be a sintered abrasive with little bonding agent) it is very easy to flatten with minimal equipment, even just lightly scrubbing it on concrete.

However as the TASK is silicon carbide, very coarse and with a weak bond that means it can be used to maintain other stones and in doing so it basically keeps itself flat at the same time. For example it readily can recondition the surface of Norton India and Crystolon stones and remove worn abrasive and make them cut again aggressively as they did as-boxed.

In summary :

It cuts fast on all manner of steels, even extremely high carbide ones like Maxamet and 121REX but since the bond is so weak it is restricted to low pressures unless there is little regard to the lifetime of the stone.

Comments can be emailed to Please Use the Forum or by posting to the following thread :

References :

1 : Abrasive grit grading systems

2 : Influence of apex grit (finish) on edge retention slicing half inch hemp

Most of the pictures in the above are in the PhotoBucket

album.

| Last updated : | |

| Originally written: | 08/15/2015 |