The Suehiro 'Chemical' is a traditional Japanese sharpening stone, which means it is an older style soak and softer stone :

there is relatively little binder in the stones: less binder - so quicker cutting as dull particles come loose and allow the fresh, sharp grit to come into play. Baked of Aluminium oxide added with bond and filler.

and :

This particular stone is quite 'old school' in the way it works, expending stone material in order to work quickly, so should be considered as 'very soft' and 'extremely muddy', which is preferred by some sharpeners, and does mean that it will not tend to leave significant scratches, making further refinement easier when the appearance of the edge and surrounding surface is important.

This is rated as a coarse stone, recommended for removing damage from the edge of a knife and in general significant shaping and removal of material. The abrasive rating is given as :

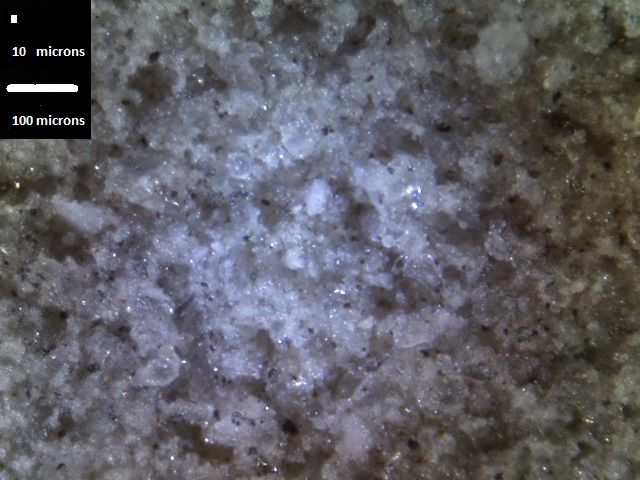

Under magnification the stone matches the description. Note how the Bester is a much more open/porous stone and the Suehiro is mainly a big chunk of more coarse abrasive which shows very little binder. However care has to be taken in trying to interpret such images without either staining/etching to actually show contrast between the abrasive and binder, or use of a SEM or similar to see the differences directly.

As a curious note about the stones, it has in bold print #800 on the box. This is often referred to as the grit however it is the part number according to Stu from TFJ and the grit from the manufacturer is 320. The visible grit is much more well matching 320 as given by Stu, as does the performance of the stone as described below.

Unlike very inexpensive stones which can often have issues with :

The Suehiro is ready to be used as-boxed without significantly lapping. It is a full soak stone, after full submergence in water it takes more than a half an hour for it to stop bubbling.

However while the Suehiro doesn't have any obvious signs of manufacturing

inconsistency :

A quick first use shows a bit of a problem

It in fact seems to behave as the completely opposite of its description.

However as with a lot of such stones

the initial surface doesn't cut

well. Many manufacturers coat stones with a sealer, this can be removed with a

little lapping, however it just as easy is removed with a little sharpening to

wear in the surface.

Initial grinding with very low pressure :

The stone barely cut as noted in the above and had issues with loading.

However with the pressure increased :

The performance of the Suehiro completely changed :

A complete reversal of behavior which shows the strong influence of

pressure on how stones cut/act and also that stones, even quality ones, often

need a little work to show the true behavior.

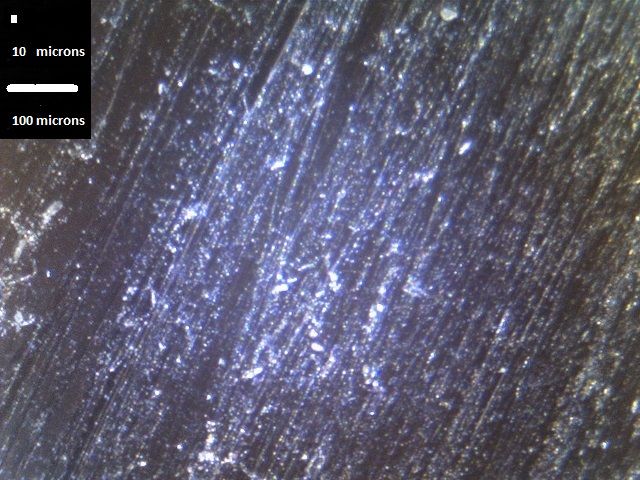

With the stone generating a slurry note the extreme contrast in how it is

able to scratch/cut the 1095 blade. It now easily grinds a very deep scratch

pattern with a very crunchy slurry, the complete opposite of the very

silty/smooth slurry which forms on stones like the Kind and Naniwa Superstone.

The scratch pattern produced is very consistent with the grit rating of the

stone 320 which is approximately a 30 micron abrasive.

In regards to the sharpness and edge retention,

it is again consistent with the above grit ratings. It produces a very high

edge retention slicing hemp due to the coarse finish which puts it in a

similar class to :

It is however a lot more difficult to get a high initial sharpness due to

the very coarse slurry impacting the edge. The most efficient way to apply a

sharp apex is to :

In general though, it is more efficient to use the Suehiro to grind the

edge and a harder stone which doesn't form a thick slurry to set the apex.

The other concern is that if the Suehiro is used to grind the edge fully

and form an apex, then it will leave the apex with a very coarse finish, much

higher than the scratch pattern. This is likely due to a combination of the

very coarse grit and the fact that it forms a dense slurry which is smashing

directly into the edge.

The images on the right show the edge off

of the Suehiro which was readily polished with a Naniwa Aotoshi 2000, a very

fine and very muddy stone. This happens very quickly and takes less than

a minute even on steels such as Elmax, D2 and S30V.

However, while the Naniwa easily applied

a near mirror polish to the edge,

the large irregular chunks which were knocked out still remained.

Unless there is no other option, a more efficient method is to use the

Suehiro to grind until the edge is almost formed and then switch to a softer

cutting stone like the Naniwa 400 or King 1000 to form the apex and then set

the micro-bevel as required. Of course this assumes that a more finer polish

is desired, if a very coarse/jagged apex is the goal then the Suehiro does

that readily and as noted in the hemp cutting, gives strong performance in

edge retention on a slice.

Grinding a basic kitchen knife (Everday Essentials Chef's knife)

to form an apex on a narrow bevel under low pressure :

Relative cutting speeds :

The Suehiro 'Chemical' 320 is significantly faster as would be expected

given it is a much more coarse grit and the pressure is high enough to allow

the larger grits to cut well/deeply. This pressure is high enough to release

abrasive from the Suehiro with simple steels. A few more checks on low carbide

stainless and plain carbon and low alloy steels < 60 HRC shows the that LCP

(lower critical point) for the pressure to cause abrasive release is ~ 2 psi.

With higher force and a greater pressure the LCP point is passed, and on

simple steels

The upper critical point, where the abrasive starts to be shed

significantly unworn, appears to be ~15 psi. At this pressure a very thick mud

builds up on the surface of the stone rapidly and will start to have both a

blending effect on the scratch pattern and will add curvature to the bevels

due to the rocking motion in the slurry layer.

Interestingly, that thick mud if left wet on the stone will form into

a very hard cement once dried, likely due to a silica based reaction similar

to found in cement. Once dried and hardened, that mud will

not then dissolve if the stone is again soaked and in fact will act as a

textured abrasive surface.

For high pressures, a stronger bond stone tends to be more optimal to

prevent the shedding of grit. For example a Sigma Power 120 working on the

same knife will reset the edge in just :

Almost ten times as fast as the Suehiro 'Chemical' 320 at 5 psi. That is

the combination of both grit (~ 3:1) and the pressure increase (~ 3:1).

The stone works very well on easy to cut steels, plain carbon and in

general low alloy carbide steels. The bond strength is well suited to those

steels and it cuts them well with minimal pressure < 5 psi. It does so at a

comparable speed to much more expensive stones. For example compared to the

Sigma Power II 240 it recuts the edge on a Svord in 15N20 in a similar time :

However even with such very light pressure the

the SPS-II still readily sheds grit and is pretty wasteful (has a low

g-ratio). As well the pressure can be increased significantly and the Suehiro

'Chemical' will still not so rapidly shed abrasive so it can easily out

perform the SPS-II on this class of steels.

However on a radically different steel is used very different performance

is seen. Resetting the edge on a 10V at 64 HRC :

The very high percentage of

vanadium carbide in 10C is harder than the aluminum oxide in the Suehiro

sharpening stone and actually wears the surface of the stone

readily.

It also wears on the SPS-II stone, but since the bond

strength is so much lower then all the worn abrasive is just released and the

cutting is constantly being done with sharp/fresh abrasive.

This is a full soak stone as noted previously, initially it took more than

half an hour for it to be saturated. It also doesn't come with the extreme

warnings on many of the modern Japanese stones warning about

hyper-fragility in regards to less than ideal drying speed or

chemical/detergent exposure. However there are clear warnings about over

soaking :

We recommend that SUEHIRO and CERAX stones not be left in their water baths too long. It is enough to put them in five minutes before use. The surface of these stones can erode if they are stored too long in water.

This was observed to be an issue with the Suehiro where it was used for

sharpening for several hours (on and off)

which meant it was soaking for most of that time

when it wasn't grinding. This put enough wear into the stone that it needed to

be lapped. A fairly basic (no name) coarse benchstone was used. However the

results were kind of surprising. The Suehiro fragmented at the edges when a

basic chamfering was attempted.

Now while this is warned about (over soaking), further experiments could

not make this repeat. The stone was soaked over night intentionally several

times and then lapped without issue. It may have been simple faults in the

stone.

The Suehiro 'Chemical' 320 :

Comments can be emailed to Please Use the Forum or by posting to the following thread :

and/or the YouTube Playlist for Abrasives/Sharpening.

Most of the pictures in the above are in the PhotoBucket album.

1

: Conversion Chart Abrasives - Grit Sizes

Finish

Cutting Speed and Pressure

Steel suitability

Cutting fluids/lubricants and durability

Summary

Comments and references

Up

Last updated :

Originally written: 09/09/2013