The soft Arkansas is a natural sharpening stone which is in strong contrast to man made stones. The Arkansas stone is simply a solid chuck of Novavulite (basically a type of rock) in contrast to man made stones which are composed of both manufactured abrasives, a bonding media and filler.

Novaculite is a sedimentary rock composed of microcrystalline quartz, it is also recognized as a re-crystallized variety of chert. It is a high-purity silica, composed of more than 99 percent pure silica. The name is applied mainly to formations in Arkansas, Oklahoma, and Texas and is derived from the Latin word novacula, meaning razor stone.

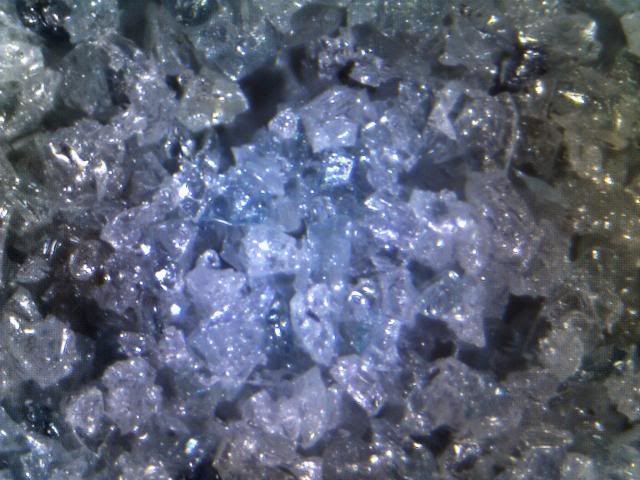

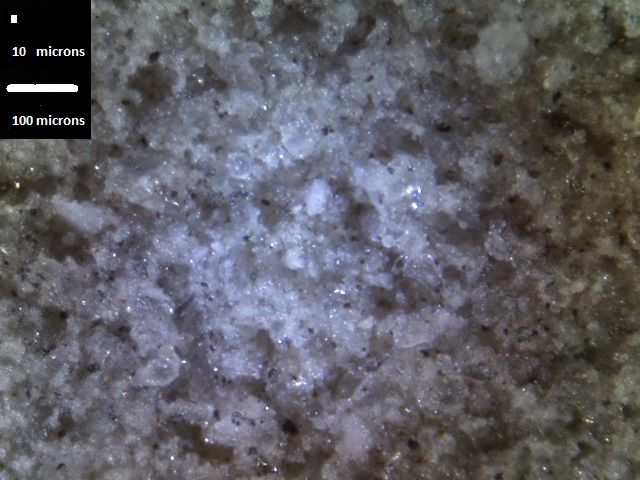

One of the most contested points about these stones is rating them by some kind of grit description. For man made stones it is pretty straight forward. A SPS-II 240X stone for example has an average particle size of 80 microns and thus the 240 grit or 80 micron label is well representative of the basic size of the individual abrasive grits which are spaced apart and act as individual cutting points. However a natural stone like the Arkansas isn't as easy to quantify.

Note how clear it is to rate the SPS-II stone even under low magnification, the grit size can just be visually estimated. However the natural stone doesn't have well defined individual grit/abrasives which can be resolved. There is a surface texture which is somewhat porous due to the nature of the material - Novaculite (a form of quartz). The abrasion takes place by a combination of the surface texture and the holes and the edges which make it naturally very slightly porous.

However it is being used as an abrasive and so what can be given is a grit rating which represents how it abrades. One way to estimate this is simply the type of scratch pattern it produces. Given that there is variation among the stones care has to be taken in giving a definite rating however most describe similar levels of coarseness :

Soft Arkansas (Equivalent to JIS 1200)

and it is commonly listed in micron ratings as 15-25 which is in agreement with that JIS rating from BDL. 2

The Arkansas stone has many of the aspects of a high quality stone as boxed :

However as for consistency of grit, natural stones are essentially just rocks and the consistency and purity of the abrasive is in general one of the ways in which they are graded. A quick check of the surface shows a low more variation than a man made stone. However there are lots of sources for natural stones, this is a very basic one and the more expensive ones are prized exactly for the consistency and density of the abrasive.

This is also one of the reasons why when the goal is to produce the highest level of finish (or polish) from a given stone, individuals will often spend a considerable amount of time with a series of abrasives grinding the surface against glass with a fine paste/slurry. With solid abrasives which are very slow wearing this is a way to manipulate the surface finish and produce various scratch patterns. If the stone is lapped with a very coarse abrasive then it will for a time produce scratch patterns which are coarse.

As an interesting point of comparison to examine the finish or polish applied by the soft Arkansas, a 1095 knife (Mora #1280) was polished :

This produced the near mirror finish on the far right. This surface was then lightly abraded with the Soft Arkansas (middle) and then the 1095 blade was repolished and then again lightly abraded with the Suehiro 'Chemical' 320 grit (30 micron) stone. There are quite a few interesting differences in the surface left by the Soft Arkansas vs the Suehiro 'Chemical' .

Looking at the surface of the Soft Arkansas compared to the Suehiro

'Chemical' 320 grit, then the reasons for this scratch pattern difference are

apparent :

The Arkansas tends to produce a very high polish due to the main surface

texture but occasional produce a large and coarse scratch from the edges of

the holes. This irregular finish is one of the main reasons that these stones

are often heavily lapped with a series of fine pastes to improve the

consistency of the finish. However in time they will just wear in use as well

and get progressively finer simply from wear of the abrasives.

This is why

they also have to be periodically recut to keep them cutting as otherwise the

surface will becomes so smooth then they will stop cutting and start

burnishing. Of course if they are desired to be a finishing stone then this

might be a positive result. As well on a stone such as this where there are

two sides, one side can be lapped periodically on a coarse abrasive and the

other side allowed to wear smooth to produce a very fine polish.

Moving beyond the polish produced and examining the finish by

Espirit baisting thread the Soft Arkansas produces a very high push cutting

sharpness, just behind the Spyderco Medium ceramic and higher than a fine DMT.

This is in agreement with the general grit ratings of the stones.

As expected, the high polish that it applies to the edge while producing

very high push cutting sharpness and cutting ability produces a very low edge

retention slicing abrasive materials. As with any stone, it has to be chosen

based on the finish provided. The very fine finish of the Soft Arkansas works

well for :

However for slicing abrasive materials then a more coarse finish can

provide much stronger and long lasting edge retention.

Grinding an edge on a 3Cr13 stainless steel knife to form an apex, the Soft

Arkansas stone was compared to a Naniwa Superstone 400 (40 micron abrasive).

The knife had the apex

cut off and then the edge reground to an apex three times. The average

performance of both stones in regards to the number of passes to form an edge

:

The Soft Arkansas is about three times slower than the Superstone in

agreement with the abrasive/grit ratio. The Naniwa also forms a very fine silt

slurry naturally which acts to prevent any burr from forming. However the same

effect also makes it difficult to set the final finish of the apex and achieve

a high sharpness as the slurry dulls the apex unless edge trailing passes are

used. It is best used as a prep stone for a final micro-bevel for another

stone. The Soft Arkansas is almost the exact opposite.

This was a very easy to grind

steel as it is soft and very low in carbide volume and it still too over five

hundred passes to set the edge even though it had no damage and was just

lightly dulled. It is obvious then the Soft Arkansas

is not going to be efficient for

significant grinding and is only efficient for micro-beveling as it is

very fine and cuts fairly slowly.

However the nice thing about the Soft Arkansas is that it is a very hard

stone and it doesn't naturally generate a slurry.

This may be a bit misleading given the name as "soft" arkansas but that

is only in comparison to the other grades of Arkansas stones, all of which are

very hard compared to other sharpening stones.

In contrast, the Naniwa Aotoshi 2000, a well regarded waterstone which

produces a similar finish can be cut into with a knife readily.

Note the

pieces cut out of the surface of the stone in the image on the right. This was

achieved with just a force of 250 grams. When using such soft stones care has

to be taken to keep the apex from digging into the surface. However it is

impossible to cut into the Arkansas stone even with much higher force applied

so it is much better to use to apply micro-bevels.

The Soft Arkansas is generally regarded as an oil stone and while it can be

used with water, or even used dry, it will load fairly readily in such

conditions. There are often complaints about oil in regards to mess, however

it has to be understood that stone doesn't need to be soaked, just a light

film of oil applied to the surface and a very neutral oil like light mineral

oil can be used.

The reason the oil is necessary for optimal cutting is that it reduces

friction. High friction surfaces cause a loss of grinding energy by producing

heat. It is a common misconception that oil stops cutting, however it should

be obvious that friction isn't required for cutting. Is an axe "roughed" up

for example to allow it to cut better or is it given a high polish and kept

clean and lubricated.

Arkansas stone are

often promoted as being fairly soft, a common statistic is

820 HK which should not be able to cut very hard and high carbide and HSS

steels. However it was readily able to cut the k390 64 HRC custom blade from

Ozark Traditional Knifeworks. As noted in the images it readily put a

microbevel on top of an edge polished with a 2000 grit Naniwa and the

sharpness increased significantly as measured by push cutting Espirit thread :

Now to be clear, the Naniwa was just used to grind the edge not actual set

the apex so the sharpness was not expected to be high. This was intentional to

provide a contrast for the Soft Arkansas. The edge off the Soft Arkansas

readily :

How to explain it :

The value given for quartz is 1181 kg/mm2, but it is larger on the m prism

faces (1260 kg/mm2) than on the basal plane c (1103 kg/mm2), an obvious

anisotropy.

This is the Vickers hardness which is approximately equivalent to > 70

HRC 1 . Why do so many people claim these stones

can not cut hard and high carbide steels? There are two likely reasons :

As these stones are just solid chunks of abrasive there is no binder so the

abrasive gradually gets very worn, the surfaces get rounded and abrasion and

cutting stops and rubbing starts. The simplest way to condition them is to

lightly rub them on sligly more coarse silicon carbide sandpaper or coarse

grit periodically. As they don't develop a hollow like soft stones, it only

requires a few seconds of work.

Soft Arkansas : Gesswein

Comments can be emailed to Please Use the Forum or by posting to the following thread :

and/or the YouTube Playlist for Abrasives/Sharpening.

Most of the pictures in the above are in the PhotoBucket album.

1

: Hardness Conversion

2

: Sharpening stone grit chart

Cutting Speed and Pressure

Cutting fluids/lubricants

Steel suitability

Summary

Comments and references

Up

Last updated :

Originally written: 31/03/2015