This review consists of :

A little history and ad copy :

Since 1823, Norton has been the leading supplier of conventional and diamond benchstones, waterstones, sharpening systems, files, slips and specialty stones for industrial, commercial and DIY sharpening applications. Our comprehensive line of sharpening and finishing products is the industry�s broadest line with premier performance and quality.

This stone is made from silicon carbide with a vitrified (glass bond). Silicon carbide is a very hard sharpening abrasive, just behind cubic boron nitride and diamond but harder than alumina, quartz and chromium oxide 1 :

For reference tungsten carbide is 1880 HK. Note that these values are not exact, they vary significantly depending on the exact structure and even the testing orientation. Typical hardness measurements can easily vary by 25% 2.

This stone is rated as coarse and fine Crystolon (Norton's trade name for their silicon carbide) :

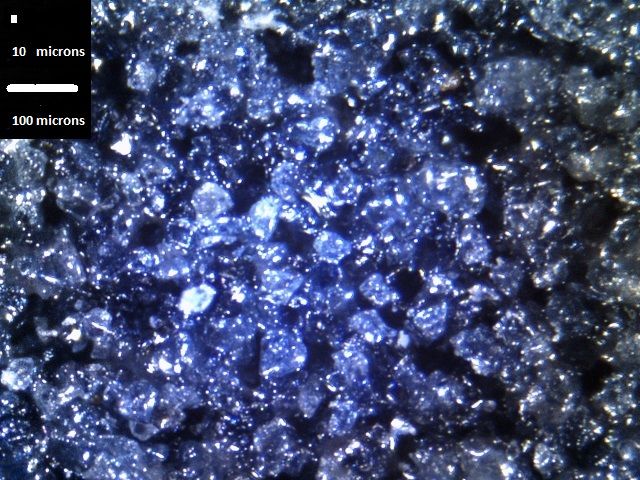

which are 125 and 45 micron respectively 3 . Under magnification the distribution of abrasive show considerable variation in size. Most of the particles fall within about 50% of the average particle size. There is also slight masking of the abrasive. It also shows a very open / porous structure which is good for both :

It does not come preloaded with oil.

Unfortunately the stone has a few issues with both quality of manufacturing and consistency. Stones are fairly simple in function and the only real functional demands are :

The Norton Economy has issues with all points :

The biggest issue is the fine side has a factory supplied dip in the short direction. This led to a section of the paring knife not getting in contact with the stone during honing.

and :

I have two of these stones. Both came out of flat in their own way. I used a tile rubbing stone to round off all the coarners on one of them.

This sample has the same issue, it is cupped on the coarse side (bowed out) and it is concave (dished in) on the fine side. The edges of the stone are also very sharp and jagged and were chamfered before use.

What is even more significant is that the bond strength is highly variable. This one has a strong bond on the fine side and an extremely strong bond on the coarse side however very different behavior is not uncommon.

I have one. It dishes too much to reprofile effectively. (At least to me) [...] The coarse side behaves like a waterstone if I use heavy pressure while its wet. The fine side isn't as bad but it dishes heavily even after a few sharpenings

and

I ground the recurve out of my Spyderco Street Beat and evened up the bevels. The stone cut fast and generated a mud fairly quickly.

Unfortunately then, it isn't possible to predict with any significant confidence how one of these stones is likely to behave in several respects.

In regards to the finish produced, it is very consistent with the above grit ratings :

The Norton Crytolon brackets the India stone well, the finish produced in ranking from most coarse to most fine :

In regards to details of sharpening :

As the Norton is a very hard stone (this one anyway) and will not tend to form a slurry under light pressure. As a slurry can act in grinding off any burr forming as it abrades into the edge, the Norton requires use of burr minimization steps need in use.

However the lack of a heavy slurry means easy to form a crisp and aggressive slicing edge with no rounding as there is no heavy slurry abrading into the apex. This is one of the largest differences between waterstones. A Naniwa 400 for example is a soft/ultra-muddy stone and it has almost the exact opposite behavior :

Grinding a basic kitchen knife (Endura/Inox) to form an apex on a bevel 1-2 mm wide under very low pressure :

The amount of passes to form an apex with both stones (an average of five trials) :

This ratio is in agreement with the micron-size of the abrasives which would be expected as in general the cutting speed is linear with abrasive size for small to medium abrasive sizes 4 .

With this pressure the fine side does generate a small slurry, however the coarse side has little to no abrasive fracturing. With the pressure significantly increased :

The cutting speed increases, but not proportional to the load :

The reason why the cutting speed does not increase even close to the increase in pressure (almost 10:1) is that at the pressure generated the stone starts to shed grit even on the coarse side and thus the abrasive is breaking apart rather than cutting. The abrasive also switches to three body abrasion where the grit is rolling against the steel vs directly cutting it.

The ideal amount of pressure on the stone for optimal cutting ability is just below what fractures the grit. However, at that pressure the cutting ability will constantly decrease as the abrasive wears. It is therefore necessary at times to increase the pressure to fracture the abrasive to get new abrasive to release readily or simply recut the surface of the stone.

As a point of reference, using the same knife with a 1000 grit / 14 micron Japanese waterstone (King), with light pressure, the number of passes to apex the same edge bevel on the inexpensive kitchen knife :

The cutting speed ratio compare to the Norton Economy Fine well matches the abrasive size ratio when taking into account that the King will be reduced in cutting speed even further as it sheds grit readily even at a fairly low pressure of ~ 10 psi.

Using the stone with water, coarse side, produces high wear on the stone. In just 7000 passes on the stone the cutting ability has been reduced to approximately 10% of the freshly cut surface.

The worn surface has stopped abrading and is burnishing. This leaves the edge with a finer finish and higher polish and could in fact be used to manipulate the finish if it was the only stone available. However in general it would be better to use a finer grit stone with sharper abrasives than using a dull grit coarse stone. While the finer finish does produce higher cutting ability on a push and the difference is dramatic the edge retention is significantly reduced.

When oil is used as a cutting fluid (mineral oil), the wear on the stone is significantly reduced and the stone can maintain a cutting action significantly longer, more than 2:1. There is also very little loading.

The coarse side requires high pressure to form a slurry. When the abrasive is sharp and the stone is cutting at optimal levels this takes place at around 50 psi. However when the abrasive is worn the required pressure is much higher as the worn abrasive has large flat contact areas which require more pressure to fracture.

As an example, with the stone in a worn condition, it was used to grind a transition bevel on a heavily damaged chisel. The contact pressure was :

This pressure is so high that it would cut a channel into softer stones easily but the Norton's coarse side excels here. Now of course the surface of the stone could be recut to also allow it to cut with reduced pressure using it under very high loads just allows it to both sharpen and condition itself at the same time.

In general (Archard equation) the rate of abrasion (Q) is proportional to the load applied (W) and the sliding distance (L) :

and thus the ability of the stone to take very high pressure without gouging enables it to cut very fast under high loads.

Restoring the chisel :

As this applies a very narrow the amount of material needed to be removed is minimized. It only took 100 passes to grind out all chips. The next step :

With the thick slurry on the stone and fresh abrasive on the surface the stone continued to cut under the much reduced pressure from the blade face :

Total amount of passes on the stone, 500. This only took a few minutes as multiple passes can be made per second.

The fine side has a much weaker bond than the coarse side and it breaks down readily in use under much lower loads. As an example grinding on a very worn Yanagiba :

This produces very efficient cutting action and generates significant slurry. However while it can cut cut at a much lower pressure than the coarse side, it can readily handle much higher pressures without gouging. Ramping up the pressure to 50 psi did not produce a corresponding increase in cutting speed as the abrasive just broken down very fast. The fine side was not breaking apart more so than cutting.

In general slurries are argued to increase cutting ability, but this mainly indirect. A rolling/moving abrasive will cut far less than one fixed in place. However if the abrasive is never released from the surface and they are not super abrasives (diamond and CBN) they will quickly wear and start rubbing/burnishing. Therefore conventional abrasives need to be able to generate a slurry to cut consistently unless unless they are frequently recut.

The Norton Economy has a low rate of wear, even with high pressure. After, 5000 passes on the stone, even under loads which generate fast cutting speeds, do not generate a visible hollow. However as with all abrasives it does wear and thus periodically the surface has to be recut so that fresh abrasive is prevented. This keeps the surface cutting consistently and prevents rubbing/burnishing. This is only necessary of course if the pressure is below or just above the LCP (lower critical point), and fresh abrasive isn't being released. If the stone is used periodically above the UCP (upper critical point), then the abrasive will be constantly refreshed as abrasive is released. However in that case the stone will eventually go out of flat.

As the stone is silicon carbide, the ideal lapping media is loose silicon carbide and very grit to ensure the surface is recut not just work down. Blasting media is readily available, 36 grit silicon carbide is easily available in most autobody stores. Another option is to use another silicon carbide stone, ideally one with a weaker bond which is much more coarse. The TASK garden stone work well in this regard and such lapping both keeps the Norton cutting well and keeps the TASK flat.

Sandpaper can be used, but frankly it is kind of insensible as the sandpaper makes a decent abrasive as well so it could be directly used instead of the stone. The ideal abrasive would be diamond or silicon carbide, however again these are kind of odd choices as they are very expensive. A DMT lapping plate for example is almost 15X the cost of this stone.

Many of the modern stones, especially the Japanese waterstones can be degraded and even seriously damaged by :

These are well known and makers, manufacturers and resellers will heavily warn about any of these on waterstones :

Do not use hot water, soap or dry with a fan. Doing so may damage the stone.

However a vitrified bond such as used on the Norton Economy is almost as robust as the abrasive itself and the stones are fairly invulnerable to damage aside from direct impact.

Silicon carbide is normally not used in industry to grind steel because of rapid breakdown of the abrasive due to the low toughness and diffusive reactions with carbon. However with hand held sharpening stones these are not really of significant concern as the pressure and temperature is much lower.

The main use of silicon carbide in sharpening stones is grinding very high tungsten and vanadium carbide steels. However this is also critically dependent on the type of bond. It isn't the case that it could be said that all silicon carbide stones will grind high carbide steels more effectively. If the bond is very strong then fresh abrasive will not be released and the surface of the stone will just wear and stop cutting. This is also very pressure dependent.

For example the Suehiro 'Chemical' 320 stone works much better on high vanadium carbide steels at low pressures than the Norton Economy even though the Suehiro is an alumina based stone. Now initially, with a freshly cut surface the Norton will cut well, however if continued to be used with low pressure the abrasive in the Norton will wear and the cutting ability will continuously decrease. However the Suehiro will shed abrasive at a much lower pressure and keep the surface cutting efficiently. Also, for very simple steels the Norton Economy is overkill and a very basic benchstone (no name brand) can work just as well.

In short :

Comments can be emailed to Please Use the Forum or by posting to the following thread :

and/or the YouTube Playlist for Abrasives/Sharpening.

Most of the pictures in the above are in the PhotoBucket album.

1 : Hardness tables, Ted Pella, Inc.

2 : Material properties of Sintered alpha-SiC

3 : Conversion Chart Abrasives - Grit Sizes

4

: Characteristics of Abrasive Particles and. Their Implications on Wear, Giuseppe Pintaude

| Last updated : | 27/03/2015 |

| Originally written: | 09/09/2013 |