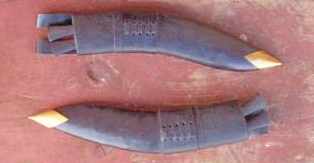

These two Service #1's khukuris from Khukuri House are the standard military model. They are similar in dimensions but different in finish. One is very rough with almost no polishing after the basic shape grinding (a), the other has the same standard of finish as found on the khukuris from Himalayan Imports, with only one problem being a large crack in the handle (b). The specifications :

| Model | Weight | Balance | Length | Blade | Edge | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| total | blade | thickness | width | total | microbevel | |||||

| (a) | 530 | 3.2 | 15.8 | 10.7 | 0.430 | 1.72 | 0.190 | 0.525 | 0.010 | 0.023 |

| (b) | 510 | 3.0 | 15.4 | 10.0 | 0.414 | 1.73 | 0.175 | 0.492 | 0.015 | 0.031 |

The lengths are in inches and the mass in grams (yes that is a mix of standard and metric - blame it on the education system). A shot of the khukuris (after considerable use) :

In respect to initial sharpness, both were very low. Neither edge would catch on a finger nail, light was readily visible reflecting from the edges and viewed side on pieces were missing about 0.5 mm deep.

Before any work could be done a couple of refinements were made to both blades. The crack in the handle of the second khukuri was first fixed by drilling small holes at the start and end to prevent further propogation, and then using wood clue to seal the crack with three applications using a 24 curing time for each. Since the initial sharpness was low for both khukuris, both were given a quick sharpening progressing through waterstones to produce a finish capable of smoothly slicing photocopy paper.

Both khukuris were used to gather some light vegetation, buck a few logs, limb some sticks, split some fresh and seasoned wood and do some carving. Compared to a small axe, the Wildlife Hatchet from Gransfors Bruks, the khukuris were much better cutting light vegetation mainly due to a longer edge, and significantly better at limbing again due to greater edge length and were generally more robust - you don't want to strike a wooden axe handle off a limb if it can be avoided. However the khuris were significantly behind the hatchet for chopping and further still at splitting. In particlar, when used with a baton the shock was many times to one greater than the Camp Tramp for example, so much so that it was problematic to split even a small round unless fresh and clear.

Used for whittling and general cutting the khukuri had advantages over the hatchet in regards to slicing most materials as the long blade length and "hook" allowed it to grasp and better cut materials such as ropes. The hatchet was however better for some wood working, but the khukuri could be used more effectively as a draw knife. The hatchet worked better at digging holes in ice, the tips of the khukuris gave solid penetration but tended to shatter the ice more than actually allow chopping out sections.

Both khukuris took significant tip bends during cutting and/or splitting, from the incidental lateral loads. When used to specifically dig and pry in woods it was readily evident that while the khukuris had better penetration than the hatchet, the points bent too easily, body weight wasn't needed, just a simple push to the side after a decently deep stab (1/2 inch) would readily bend the tip.

The khukuris were used alongside the Wildlife Hatchet for an extended session of wood chopping to better gauge their performance. From just a few shoulder driven chops it was apparent that the penetration of the hatchet on solid woods was significantly higher. Through repeated cutting over the course of several weeks an estimate of 54 (13)% was obtained for the performance of the khukuri in respect to the ability of the hatchet in regards to the number of chops. The time has an almost identical ratio as both blades were fluid in the wood. Most of the cutting was done on two to four inch seasoned fir and spruce, one to three years dried.

On lumber, the rough ground Service #1 was compared to a number of chopping tools including the Wildlife Hatchet. The khukuri did very well on very slight clapboard as the hatchet tended to shatter it, but as the board got thicker and able to take the impacts of the heavier chopping tools then the khukuri fell behind and the chop ratio agreed with the above performance obtained on felled wood.

The issue with lots of vibration during baton turned out to be one with the center of percussion which is the point at which the blade can be struck and it will simply tend to move as a whole rather than vibrate. The point was located on the khukuris, it was just slightly ahead of the hump. If the blade was struck there when batoning no excess vibration was induced. However to use this point for the baton strike zone, the khukuri must do the actual wood splitting with the recurved section in front of the handle. This isn't an ideal blade profile for splitting wood, in addition this area of the blade isn't usually intended for heavy use and is thus left softer than the main section of the blade (forward of the hump).

To examine if this issue was significant when chopping or hammering, both khukuris were used for chopping into heavily seasoned woods and hammered into the same with the edge reversed and striking with the spine, at various locations along the edge forward of the hump. While the vibrations did increase as the impact points were moved away from the comfort zone they were never significant enough to effect the security of the grip. The reason that the vibrations were amplified during the splitting may be simply due to the much lower penetration during splitting as the longer the duration of an impact the lower the impulse produced. In any case, a number of straight blades were tended for similar splitting and found to be far less sensitive to the position of the impact point when batoning in regards to inducing vibration. In short they were thus more functional with a baton.

The blades were honed readily to sharp edges (easily slicing fine paper), and the edge retention was observed to be solid even on knotty wood with no visible damage. Specifically both khukuris were used to hack wildly on a frozen stump in order to stimulate the worst possible senario, a loss of fine motor control in high stress or excited situations which results in using far more force than necessary. This was of course done only after regular chopping with care failed to produce no significant edge damage.

While doing very well in the wood cutting, in more extreme situations the edge took damage readily. Specifically, when used for creating shavings during firestarting the khukuri grated accidently along a jagged rock after too much force was applied into the cut. The edge fractured showing glass knapping like pressure flakes up from the edge. Some light chopping into a concrete block revealed that this low ductility and impact toughness was consistent along the edge which would readily fracture even if the blade was basically dropped from 1-2 feet under its own weight.

Damage was also observed in cutting roof flashing, and impacts into small nails. Specifially on the nail cutting, the khukuris could not cut the nails anywhere near as well as the Deerhunters from A.G. Russell, and required a lot less force (multiple times the number of hits) to prevent damage. Trying to cut thicker nails (3.5") was impossible as the edges on the khukuris would simply fold over even if light impacts were used, even lighter than the impacts used by the Deerhunter which readily cut those nails in under thirty hits.

The khukuris were wedged into an overhead rafter and an attempt was made to do a pullup (~185 lbs). Both khukuris took a significant bend before full extention so full body weight was never applied. The bends could be pounded back by placing the khukuris onto a round of wood and hitting them with a stick to straighten. Later they were chopped into an old stump and various prying done to again check the resistance to bending, both bent readily with little strain, however they could again be restored to true by prying in the opposite direction, no cracking of the edge was observed.

The main problem with khukuris of this size in general is that the handle can be too short for hammer grips. In general lots of people have problems with khukuri grips, it is common to see complaints about the abrasive nature of the central ring, or that the grip can turn in the hand. The latter isn't usually a problem with the inherent nature of the grip but more so that the dramatic curvature of the khukuri blade can take some getting used to for someone experienced with a bowie type blade. The solution is simply to keep the impacts low until enough experience is attained. In regards to the buttcap, they loosened on both khukuris within a short period of time (less than an hour), no direct impacts, simply the normal vibration from chopping. After the drilling and gluing, the crack on the one khukuri was stable even after much chopping and pounding.

The khukuris came with the standard wooden and leather wrapped scabbards, which fit both blades tightly (could not readily shake them out) :

The frogs (belt loop harness) were of two radically different designs :

On one it was riveted to the leather band around the scabbard (the bottom one in the above picure), on the other the straps were part of the band and securely loosely with two eyelets. On that one the attachment was weak and the straps could easily be broken off by hand. The strap cuts went down into the main band making a large weakpoint).

These khukuris are very similar in dimension and nature to a Service #1 from Gurkha House. They can take a decent edge and to a large degree handle in a similar manner in cutting and chopping as the khukuris from Himalayan Imports. However the Khukuri House models tended to take edge damage more readily and the main blade body was also much more readily permanently bent. Both of these are likely due to heat treatment issues. There is also a durability concern with on of the frogs due to the nature of the attachment of the belt straps.

Comments can be sent to : cliffstamp[REMOVE]@cutleryscience.com and made in the the following thread :

| Last updated : | June 23 : 2006 |

| Originally written; | Fri Apr 16 14:18:06 NDT 2004 |