A shot of the fourth generation Endura (top) and Delica :

The fourth generation Endura has some a long way since the origional implementation. It now features a redesigned handle, different contours and checkering pattern, a more ergonomic clip, with a VG-10 stainless steel blade, and the grip has dual steel liners and torx screw construction. From the Spyderco webpage on the Endura :

The Endura changed the way the world makes folding knives. When Spyderco released it in 1990 people poked fun at its untraditional appearance and features. It introduced one-hand-open, lightweight folders to the knife buying public offering tremendous performance for dollar value. Since then the Endura has undergone many evolutionary refinements and upgrades retaining its title as the first (and quite possibly the finest) lightweight one-hand open, folder available. The VG-10 blade is flat saber-ground for a strong cutting edge and comes in a PlainEdge, SpyderEdge or CombinationEdge configuration. Textured with a volcano grip pattern, the handle is injection molded from black FRN that resists temperature change and chemical exposure. Completely ambidextrous, the black metal clip affixes through the landyard hole for left/right-hand, tip-up carry.

The Endura has an overall length of 8 13/16", is 4 15/16" long when closed, has a blade length of 3 15/16" and a 3 7/16" cutting edge. It weighs 3.0 oz and is made from 1/8" thick VG-10 stainless steel with a FRN grip. The opening hole has a diameter of 15/32". The primary grind is sabre-flat which tapers to an edge from 0.015-0.020" thick and ground at 16.4 (1.4) degrees per side. The tip is fairly robust being 0.44" wide with a 0.64" long taper.

Push cutting 3/8" hemp required 26 (1) lbs, with no reduction on a draw which corrosponds to the low aggression on the cotton. The performance here is fairly low due to the below average initial sharpness.

On birch hardwood with heavy exertion, the Endura took 30 (3) slices to make a point on a 1x5=5.5 cm section. This is fairly standard for a utility profile and could be significantly improved by adding a relief grind to the edge if desired.

The point on the Endura is fairly robust due to the sabre profile however with a 50 lbs push it still sank 165 +/- 7 pages into a phone book and with a hard vertical stab penetrated 567 +/- 37 pages. This is significantly lower than the fully flat ground blades with a distal taper like the Paramilitary which gets 227 (8) and 689 (16) pages respectively showing about a 25% improvement in tip penetration. This is a common trade of cutting ability vs robustness.

For reference here are the results of similar work with the Delica from Spyderco which is essentially a smaller version of the Endura :

| Model | sharpness | Manila hemp | Phonebook | hardwood | |||

|---|---|---|---|---|---|---|---|

| thread | cotton | push | slice | 50 lbs | stab | ||

| grams | inches | pounds | pages | slices | |||

| Endura | 186 (6) | 3.4 (2) | 26 (1) | 26 (1) | 165 (7) | 567 (37) | 30 (3) |

| Delica | 88 (11) | 0.20 (4) | 24 (1) | 13 (1) | 185 (6) | 604 (34) | 26 (3) |

Both knives have similar edge angles, the main difference was the Delica had a much higher initial edge aggression which is reflected in the cotton and hemp work. The difference in wood carving ability was mainly due to leverage issues with the grip. Comparisons to other knives can be seen in the various reviews and the above linked pages.

The Endura is a bit big to work efficiently as a paring knife, it can peel potatos without any issues such as overly thick skins, but extended use does produce a desire to get a more optimal knife. While it does balance well for peeling, not being too blade or handle heavy, the blade is too wide the Delica works much nicer :

However in general the Endura handles slicing and dicing well, there is some cracking when cutting potatos, however not so much that it prevents slices and cubes :

In terms of raw cutting ability, the Endura takes about 8 lbs to slice medium potatos while an optimal designed utility kitchen knife will only take about one pounds, on carrots it is 3-4 lbs vs 9-11 lbs. This is enough to be easily felt, but only a real issue if a lot of vegetables had to be prepared or if the vegetables were really large like turnips. On softer foods, the Endura worked well, cutting up onions, it has enough length to make full cuts easily and the blade has no problems making thin slices and dices :

Though the traditional way of cutting horizontally is problematic as the profile is too thick so for fine mincing the cuts need to be repeated. Working with precooked foods like baked potatos, the Endura does well, here all that is required is mainly a very sharp blade to cut the skin well :

It also slices up bananas evenly without cracking them :

and slices and cores fresh apples, though a finer point would be of benefit :

It also works well on sausages and other meats which require a very sharp blade to make cuts without excessive slippage, there were also no problems maintaining control of the Endura even when the handle was covered in grease, fats or blood :

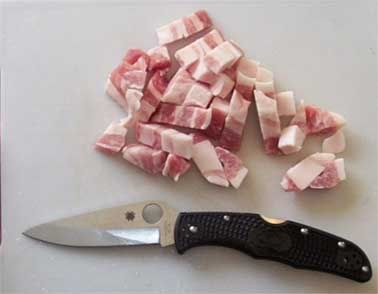

and some pork :

The robust tip on the Endura also has no problems with harsher work and opened a tin of ham with no edge damage :

The grip was solid during the above work with no concerns about comfort or control and the handle was easily rinsed clean. The steel also resisted corrosion even when left wet and exposed to various fruits juices and as well cut various raw meats without being immediately rinsed and dried.

The Endura doesn't have a lot of chopping ability, on plywood lats it took about 20 hits vs 15 slices to cut off a section. It could chop about 3/8" green pine branches in a few swings and had enough chopping ability to cut alders for poles and thus it would offer significant benefit over a much smaller knife like the Delica.

However on harder or larger woods a baton needed to be used it on its own it only has about 85 (4) % of the chopping ability of the Mora 2000. the Endura is close to the Mora as it has much more heft in hand, however the Mora is about 50% more effective with a baton due to the thinner grind. Before any wood is chopped though, and even after a decent amount of snow :

dry wood can often be gathered with some searching. Usually going under heavy tree cover is enough, cut some green boughs to lay on the ground if necessary or a large piece of bark to work as a base. The Endura is well appreciated to gather grasses for tinder, bark, as well as cut shavings for tinder or remove the outer wet shell of woods, lightly pry part rotted woods, and trim boughs green boughs. Once a flame has been started add various broken dry woods to keep the fire going :

The larger wood can be fire cut to length by placing it across the fire and as it burns through just move the pieces into the main flame, taking care as always when working around open flame. However small dry wood of a few inches in thickness won't last very long, especially if there is even a light wind. In order to sustain a fire for a few hours it is necessary to either cut larger wood, or better yet find wind blown trees, rotted is best and just them to keep the fire going :

The large round placed across the fire in the above burned for about 6-8 hours until it was mainly embers while every 1-2 hours an armful of smaller wood was thrown on to stir up the fire. Of course the nature of the wood will influence burn times very strongly, dense hardwoods can burn for several times longer than open grained softwoods. As the wood burned the location was mainly cleared of debris and scouted for items of interest such as :

These two deadfall trees are essentially a ready made shelter, the first step was to trim the branches from the front and underside and use them to fill out the back. This cleared enough room to serve as a place to sleep protected from the wind and snow. Even with this first step, which takes just a few minutes, it makes a major influence on snowfall (but does little for rain) and will act as a weak wind break :

As the tree is dead, the branches are easily cracked by bending them backwards. If a larger knife or axe is on hand the process is much more efficient as they can basically all be swept clean in just a few passes. A saw is handy to have as well rather than an empty hand, but takes much longer than a long knife or axe. The next step is to fill in the front, which takes about 15 minutes to get it to the same degree as the back :

This gives a decent amount of cover from the snow even with a high wind. It will reduce inches of snow fall to just a few millimeters however to provide a decent amount of actual heat insulation and to offer any chance of protection from rain the bough cover needs to be much thicker. Any vegetation (or materials if the site is more urban) can be used, in fact once the basic frame has been built it can be filled out with snow which will work very well unless there is a heavy rain.

It however takes a massive amount of boughs to provide significant rain cover as in at least a foot, and it only really works well when they are green and very thick. very large leafy plants works better as does large pieces of birch bark. Improvising is always useful, a few garbage bags cut open and layed down over the first cover and then overlayed with more boughs will provide a very solid rain break.

As for having to work with very thick woods, a lot of wood can be split using wooden wedges, which are readily carved with the Endura :

A crack is started in the wood if an existing one is not present and then the edge pounded in with a rock or another piece of wood. If the wood is soft and easy to split like Pine then usually one large convex wedge is enough to handle even 6-8" rounds, however if the wood is tight grained like Oak, it is usually much more efficient to use much slimmer wedges and more of them.

The Endura works well for general utility work, it cuts Cat5 cable with 42 (1) lbs and easily chews up a pop can or food tins as noted in the above. However the profile was a little thick for heavy plastic. Even with 150 (5) lbs applied it can't cut through the bottom of a 2l pop bottle.

However it readily cuts through the end of a 591 ml bottle readily. Trying the knife out on other various materials, the effectiveness of the cutting ability was examined with both a high polish and somewhat rough edge using the Sharpmaker medium and fine rods to supply both finishes. A rawhide glove, rubber sandall, roll of cotton sheet and sheet of cardboard were cut up in various ways :

With a highly polished edge, the rubber sandal was cut with three passes under light force, to be specific the sandal was bend with 10 lbs applied and the knife was drawn across it on a slice so light that it would not show on the scale (less than half a pound). With the edge with the medium finish the blade cut much better and onlt two cuts were needed.

On the cotton, under 25 lbs of tension, the roll only needed 1.6 (2)" of blade to make a cut, with the medium finish. The aggression was high and there was no slip of the blade, just a smooth cut. With the high polish the cut was not as aggressive, however the push cutting ability was so high that the blade pretty much went through the cotton as soon as the tension was applied and only 1.0 (2) " of travel was required to make a cut.

On the leather, the blades cut with similar force and blade length but in different manners. The medium finish started clean with no travel and cut the leather in a consistent slice with little effort on a draw. the polished edge slipped a little initially, but once the cut was started it went through the leather easily and required less of a draw than the rougher finish.

On the 1/16" ridged cardboard, with the high polish the Endura needed 5.0 (5) lbs to make a push cut with the blade perpendicular to the cardboard and held at a 45 degree angle to the vertical, and 10 (1) lbs with the medium finish. There was no reduction in force on a slice with the high polish and the force dropped to 5.0 (5) lbs on a slice with the medium finish. With the blade held at 45 degrees across the cardboard as well as in the vertical, a push cut was made without moving the needle on the scale (less than half a pound) with the fine finish and similar for on a draw with the medium finish.

In short, the materials were not as important as how they were cut, the materials only mattered if they could only be cut one way. Thick rubber for example is near impossible to push cut and requires a draw, this means that a more coarse edge is more optimal both for initial cutting performance and extended cutting ability, it will cut better for longer.

As a rough pass at edge retention, with a highly polished edge with the origonal edge angle, the Endura was used to make a pile of shavings :

and then split a bunch of lumber :

with direct hand pressure of up to 175 lbs applied :

and could still readily slice newsprint :

NOTE the splitting methoded used places the hand over the point, which is fairly dangerous and only possible here due to the particular dropped point style of the Endura. It is much safer to baton the blade through the wood, which is however much harder on the lock of the knife. It can be done without loading the lock by disengaging the lock and just pulling down on the handle.

However cutting that much wood isn't very difficult in general as most wood isn't overly abrasive, so moving onto a more abrasive medium, with a freshly polished edge, seventy five cuts were made though 1/16" ridged cardboard, 27 m in total were cut :

The Endura could still readily cut strips from the underlay of a SUV :

This did induce enough wear on the edge so that 10 passes per side on the medium rods of the Sharpmaker were required to reset the edge which was then polished with the fine rods to a high finish in the same amount of passes.

Much work with the edge retention of VG-10 has been done with other Spyderco knives which shows solid performance over a wide range of media.

The Endura's primary edge is honed at a low enough angle so that it can be sharpened on the Sharpmaker directly. The machinability of VG-10 is high compared to steels like S30V and in general it gets consistent praise for ease of sharpening and ability to take a high sharpness in general. There were no problems sharpening the Endura even on traditional Arkansas stones.

As a more drastic application, the Endura was used to cut a one foot square sod in the most brutal way possible which was use it like a root saw, the edge was constantly grating over rocks, and then the sod was skinned off. It had no push cutting ability on the hemp, 150 lbs didn't even score it, and it took 30 full length slices at 30 lbs to make a cut. It was then sharpened it with thiry seconds per side on a concrete block :

and would then make the hemp slices in 2-3 blade lengths, could push cut with about 90 lbs, and easily cut newprint on a draw :

The concrete had large rocks which would pretty much mash into the edge and flatten it, you need a section which is mainly sand and there was none on this block for optimal sharpening. About a half an hour or searching located a flat rock which honed the Endura and allowed the hemp rope in under a full slice.

The Endura is one of the classic Spyderco grip shapes its strength is in its versatility, unlike the Military and Paramilitary which have more indexed grips due to the extensive contouring :

The Endura is well suited to the basic hammer and sabre grips, as are most knives, however the large handle on the Endura which is a full 4.8" of usuable grip which makes it functional even with a heavy glove or even winter mitt :

The Paramilitary can't be used with such a mitt and even has problems with a heavy glove in hammer and sabre grips as it needs the front index finger cutout to allow a full grip and this region is a bit small for a mitt and heavy glove. The Military however as a four inch grip region without the integral index finger cutout and thus works well even with a heavy glove or mitt.

Back to the Endura, the versatility shows itself in the ease of functioning in grips in which the hand is reversed and the contours face the inside of the palm such as the icepick :

The curved end jook also works well for extra support by wrapping the thumb which acts as a secondary method of retention

A laynard can be used for even greater support if needed. However the aggressive checkering on the FRN which is directional biased, tends to make these not necessary as fully power thrusts were readily possible with a sabre grip even with the handle lubricated with liquid soap :

Very hard stabs in an icepick grip were also possible though there was some slipping and the grip had to be reset after ever 2-3 stabs :

Security could be enhanced by changing the ridges in the FRN grip behind the thumb ramp, they are too coarse to aid much in retention and would be better suited on the undersided of the grip. Note however as with any texturing which enhances security there are likely ergonomic issues with extended utility cutting.

The Endura has the same lock as found on the Delica and the action and security was was much the same. There are no issues with spine whacks, and is it stable under white knuckling and torques. However lockbacks have been noted to fail due to debris contaminating the lock bar cutout so the Endura was placed in a cloth bag with a cup full of lint from a dryer. The bag was shaken violently for thirty seconds and then the knife opened and the engagement checked visually and then with a spine impact on a piece of wood :

After the first period of shaking there was visible lint in and around the lock but it was not until the sixth round of shaking that the lint caused the lock to not engage fully and and a slight gap was seen, however the engagement was still secure. After the eight round the lock bar jammed and failed to engage. With the blade fully opened, the lock bar could be seen to be a full eight of an inch above the handle due to a significant amount of lint in the notch and in the general pivot area.

The knife was cleaned in seconds using a toothpick to remove the lint, the lock then engaged normally and passed all tests of strength and security. The lint bag shaking was repeated a few more times. Once lock engagement failed after six shakings, and once it took until ten. About eight seemed to be the average point at which the engagement would outright fail or at least strength would be compromised. In short it is readily possible for the lock bar to jam with pocket lint but it seems to take fairly extreme circumstances.

This aspect was also looked at from the point of view of general debris, and the ease of cleaning with a more aggressive form of debris. The knife was placed in a small box with enough soot from a wood stove to cover the Endura completely and the box shaken for ten seconds. With a light rap of the knife on a piece of wood the lock would again engage as normal. The lock bar was then hand packed with soot :

Again just a sharp rap and the knife was fine, a half a dozen times showed no net effect. Finally water was used to make a paste which was hand packed around the pivot and then rubbed all over the handle :

A sharp rap and again the knife was fine, the muddy handle was also secure in hard stabs and thrusts. Cleaning took some rinsing, and using the run off from the soap used to clean the hands, the handle was fine in a few minutes. The action of the knife was not adversely effected by the contamination.

The clip on the Endura can be attached to either side and positioned for tip up or tip down carry. The folder is both small and light, and can even be clipped to the tip of a shirt and carried . No problems were noted with security of attachment or ease of draw.

The Endura is a small utility knife with high initial sharpness, solid cutting ability, quality ergonomics and grip security. This model is signifiantly upgraded from the introduction of the Endura by Spyderco and has a higher grade of steel, a more ergonomic clip and uses torx screws rather than a pinned construction.

Comments can be emailed to cliffstamp[REMOVE]@cutleryscience.com or by posting in the following thread :

More information can be obtained at the Spyderco website. There is also a passaround thread on the Delica which may be of interest :

| Last updated : | 01 : 10 : 2006 |

| Originally written: | 01 : 05 : 2006 |