A shot of the R. W. Clark Model 10 in Liquid Metal (LM1) from the side :

and from the top :

The Model 10 from R. W. Clark in Liquid Metal (LM1) has a dropped blade. It weighs 160 g and has a handle heavy balance centered 2.5 centimeters back from the guard. The primary grind is full flat on 1/8" stock. The blade is 1.3" wide and 5.25" long. The edge thickness and width vary from 0.021" to 0.027" and from 0.029" to 0.039", the tip is strongly asymmetric due to the variance in edge width. The edge angle is however consistent at 18.5-20.5 degrees. Under magnification (10x), the edge is clean, no burrs. There is a steeper secondary bevel. The spine is ridged just ahead of the handle and through the end of the tang for security. The handle slab fit to the tang is perfect, everything is flush. The slabs are bead blasted to produce a nice secure yet non abrasive coating. The spine is squarish and fairly sharp. The Kydex sheath is well formed, no rough edges, though there is a little blade rattle.

On 3/8" hemp, the Model 10 took 80-90 lbs was required with a rocking push cut through the tip, 90-100 lbs near the choil, and 40 (1) lbs on two inch slice. After sharpening with 22 degree micro bevel with a fine ceramic rod, the Model 10 required 26 (1) lbs for a push cut through the tip and 17.5 (9) lbs on a two inch draw. With a 600 DMT finish, 30 (1) lbs was required for for a push cut through the tip and 14 (1) lbs lbs on a two inch draw.

On hardwood dowel, with a 22 degree fine ceramic micro bevel, the Model 10 needed 6.8 (3) slices to make a point.

The tip got 687 (56) pages on a vertical stab into a phone book. Digging in 2x4's was not attempted, later work showed fracture readily.

The penetration on a chop into small woods was estimated to be about 20 +/- 2 % of the ability of the Wildlife hatchet from a comparison done against the Camp Tramp on small woods.

In the kitchen the dropped blade profile allowed full and deep cuts to a cutting board. W The combination of decently thin stock and efficient edge profile produce solid cutting ability which fared well. The only drawback to a truly optimized kitchen knife was seen on thick and binding vegetables. On a medium sized turnip the Model 10 took 16 (1) lbs on a push cut while the Japanese utility knife only required 7.0 (0.5) lbs. The lack of rounding on the spine of the Model 10 could also be felt with the heavier push cuts.

The Model 10 was also used to take apart various poultry for stocks, soups and baking. The handle stayed secure even when covered in fat and grease and was comfortable throughout the cutting. The thin tip easily penetrated the skin and meats efficiently and made readily cut in between joints. The upsweep was a bit high for removing the breasts which was done more efficiently with the Pronghorn. A Blackjack Small was also more deft around joints due to the shorter blade. The thin point of the Model 10 did proved to be especially efficient cleaning some trout and was much more functional than a Camp Tramp for such work.

The Model 10 was also used to pry the meat off the inside of coconuts. The very thin point was able to readily get between the meat and the shell. Thicker blades like the Camp Tramp could not do that and just tore up the meat. However the Camp Tramp was able to open the coconuts readily by chopping. A Blackjack small attempted to pry one open and quickly broke off a section of the tip.

The high corrosion resistance of LM1 was of considerable benefit here as many fruit juices are acidic enough to induce a visible patina in minutes on steels like 52100 with even just moderature use so edge retention is in general low for those steels in cutting acidic foods.

On light vegetation the Model 10 cut well. The main problem was lack of reach and not enough blade balance for the heavier stalks. Most light work was more productive with the blade pinched sideways and the material cut with a flick of the wrist. The high corrosion resistance is of benefit on such work as some plant juices can be fairly acidic. The grip was ergonomic and secure for such work, even with lubricated both with sweat, juices and saps and artificially with liquid soap.

Carving woods, The Model 10 had slightly greater wood roughing ability than the Camp Tramp as illustrated by the dowel cutting, however the main difference was that to achieve the highest level of performance with the Camp Tramp it had to be used in a choked up grip around the index finger cutout. The grip isn't very ergonomic in this position, mainly due to the squarish nature of the front of the grip (its almost perpendicular to the blade), and of course the index finger cutout isn't as comfortable as a grip around a full handle. When the Camp Tramp is used in a full grip around the handle, the wood roughing ability is vastly reduced due to the leverage disadvantage of having to cut far in front of the grip (about 80% for my hand width).

For chopping, on some soft woods like Alders, the Model 10 could chop down small sticks (under an inch) readily, but on slightly harder wood of decent size to make shelters the knife was not overly efficient. Getting more specific, the Model 10 was used along side the Camp Tramp to knock down a few small trees from 1.5 to 2.5" in diameter (pine, spruce and fir). Both blades were compared to a the wood saw on a Rucksack. The Model 10 had about 21 +/- 5 % of the ability of the saw (comparing times) and the Camp Tramp 140 +/- 6 % of the ability of the saw. The performance difference was significantly greater than the above raw penetration because the Model 10 could not achieve enough penetration to clear out the necessary full wedge and thus had to consistently multiple notch the cuts.

The Model 10 was also used with a baton for some chopping which greatly increased its functionality. The impacts were light at first, but some were heavy enough to readily break off the batons about two inches thick. No visible damage to the knife. The very tip was avoided in the impacts, focused the impacts at least 1/2" back. The difference in chopping performance was also readily noticed when gathering tinder from dried wood. The Camp Tramp had enough power to easily split slabs and smaller pieces from sticks many times faster than the Model 10 which had to cut them off, or needed use of a baton, which is awkward as it doesn't leave a free hand to steady the wood.

As a splitting tool, the Model 10 was batoned through some clear wood both scrap lumber and felled wood. The knife has little inherent splitting ability as the profile is very thin, however with aid of a baton it was efficient enough at small wood for fire starting. Some knotty wood was also cut, still small rounds, and the edge on the Model 10 durable enough to chisel right through small knots (2-3 mm thick), which took fairly forceful hits.

For limbing : the Model 10 was easily enough blade to limb out trees shelter build size (one to three inches thick), even the decently harder ones like spruce. The limbs were small, usually 1/2" and under and could be knocked off in a hit or two. The knife was usually swung in a partial grip, but was used in a full grip to sweep off the smaller branches. No visible damage was induced even on the well seasoned smaller branches.

On light barks like birch, the Model 10's more precise point and overall lighter blade was more efficient at removing large patches than the more robut point on the Camp Tramp. On bark under 1/2" or so thick the Modeal 10 could easily be inserted under the bark and leverage up pieces until large pitchy slabs could be broke off which are excellent for tinder. The Camp Tramp needed significantly more force to be inserted under the bark, and due to the cross section tended to fracture it a lot more. However on really thick barks, the Camp Tramp's more robust point was easily able to quickly tear off large chunks, whereas the Model 10 was much more inefficient due to the lack of stiffness of the tip (mainly a cross section issues however also inherent materials strength).

As a prying tool, the Model 10 was limited. The tip strength was checked on a piece of clear pine (lumber), and it was unable to clear the wood from 1/4" deep penetration, the tip just bent. The extend of the bend was about one mm to the side which extended the entire depth of 1/4". On a harder piece of wood, a deeper stab was used, 3/16" of penetration, and the knife again failed to clear the wood and the tip just took a bend to the side (opposite direction). This time the tip was deflection ~2 mm to the side and again extended the full depth of penetration, 3/16". In contrast the Camp Tramp's very robust tip was used to break apart rotten trees to get at the ant riddled core. This wood is almost paper light and can be used as excellent tinder, even paper, and for makeshift strainers. The knife was able to break open the main tree body with body weight prying to the side. It also broke/tore open stumps and trees readily to get pitch wood, also excellent tinder. It was also used to pry free large rocks while digging a small fire pit and looking for worms for fishing .

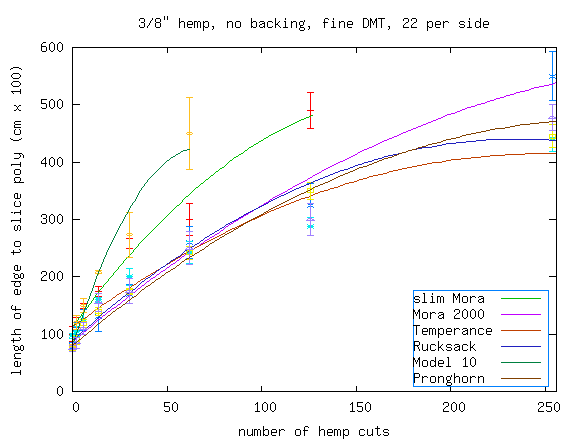

The Model 10 was used to slice through free standing 3/8" manilla hemp with both a fine and x-coarse micro-bevel at 22 degrees from DMT stones :

| # cuts | fine DMT | x-coarse DMT |

|---|---|---|

| edge length (centimeters) | ||

| 0 | 0.78 +/- 0.04 | 1.02 +/- 0.16 |

| 2 | 1.20 +/- 0.12 | 1.27 +/- 0.16 |

| 6 | 1.50 +/- 0.13 | 1.55 +/- 0.14 |

| 14 | 2.08 +/- 0.03 | 1.70 +/- 0.09 |

| 30 | 2.73 +/- 0.39 | 2.12 +/- 0.19 |

| 62 | 4.50 +/- 0.63 | 3.88 +/- 0.56 |

The edge retention improved as expected on the more coarse finish but it was still very low compared to steel blades in general. For reference here are the fine (600 grit) DMT results compared graphically to several other steel blades :

On used carpet, the Model 10 cut on a draw with the edge as finished 600 DMT rod set at 22 degrees per side. The performance was significantly behind several steel blades. The Model 10 took edge damage, with the chips ranging in size from 0.1 to 0.2 millimeters in depth. The edge sharpened readily, with the edge recut with a 1000 grit waterstone for about two to four minutes to remove all signs of damage.

On 1/8" ridged cardboard, the Model 10 was used to slice across the ridges over a one inch section of blade held at a 45 degree angle during the cutting to enhance the slicing ability. The sharpness was measured by push cutting light baisting thread. An Extra Heavy Duty Olfa knife was used as a reference. The Model 10 was honed (15 - 16 degrees per side) on a 1000 AO waterstone then the edge refined on a 4000 grit waterstone. It was then stropped lightly, 12 passes per side on leather loaded with 0.5 micron chromium/aluminum oxide buffing compound. This left a very fine edge which shaved well and had some bite left over from the waterstones. The Olfa knife had the factory edge, similar in micro-tooth level to the Model 10. The Olfa blade was tested in two unused sections, however its performance is a little less than optimal as other sections of the blade had been used for various work and some corrosion could be seen along the flats. Two runs were made and the results consistent. The Model 10 was clearly outperformed by the Olfa knife in retaining sharpness through the cardboard cutting. Details :

| Model | Force on thread cutting | ||||

|---|---|---|---|---|---|

| grams | |||||

| Initial | 1.3 m cut | 3.9m cut | 9.1 m cut | 19.5 m cut | |

| Model 10 | 142 +/- 5 | 222 +/- 13 | 232 +/- 15 | 325 +/- 41 | 385 +/- 66 |

| Olfa | 107 +/- 7 | 117 +/- 15 | 160 +/- 45 | 220 +/- 18 | 252 +/- 60 |

However the Olfa knife did tend to bind or wedge more on the cardboard. The Model 10 had just enough blade stock thickness to induce a light splitting of the cardboard which greatly reduced retarding forces along the blade. On the Olfa, since it has no primary grind and is just blade stock, there is a lot of friction along the flats. Of course there are other Olfa knives that are more suitable for cardboard, specifically the normal cutter which is only 0.3 millimeter thick as opposed to the 0.7 millimeter thick blade on the Extra Heavy Duty knife, which is made for generally harder cutting tasks on thicker materials where more lateral forces are exerted on the blade. The large uncertainties in the results of the thread cutting are because as the thread is so narrow it only tests a small section of the edge and as a knife blunts the edge deforms in a very inconsistent manner due to the nature of blunting. To get more stable results more thread cutting would need to be performed and more runs averaged.

On woods, after fairly brief chopping sessions (100 or so chops) the Model 10 was examined under magnification [x10]. The edge would consistently chip out at an extent of 0.05 - 0.1 millimeters deep and about one millimeter long. These would have a frequency of about one chip every five millimeters or so. The edge retention when whittling very hard woods was also not up to par with a much harder cutlery steel (yes fairly vague - should quantify that).

Various types of fabrics were cut with the Model 10, usually with a high polish and little slice. It cut those materials well, from burlap sacks, seat belts, to thick leathers, various paper and cardboards. The knife had no need of angle cutting when sharp and could simply press straight down into the material. The thin point also penetrated well and could for example be used as an awl on leather much more so than the Camp Tramp which is hindered also due to its weight and size.

The thin and acute tip on the Model 10 also proved to be very handy on opening boxes as it would penetrate easily and allow shallow cuts effectively. It could also readily remove larger staples being easily inserted under them. For these kinds of tasks the knife was much more efficient than the Camp Tramp. However the more robust point on the Camp Tramp was more functional when removing very heavy staples and nails from woods, and in general can be substituted for a light wrecking bar.

During fixing a front step the Model 10 was used as a probe to check for depth of rot however it was not capable of serving as a pry bar due due to the stock thickness and low strength/ductility of LM1. This limitation was also seen with the inability to remove horseshoe nails from a barbed wire fence. The edge also didn't have the necessary strength or durability to easily cut the wire due to the materials low hardness and brittle nature.

However cutting SM and other styrofoam insulation the Model 10's slim point easily scored the material, and was much more efficient cutting the insulation than the Camp Tramp which has simply too thick a profile as this material wedges very tightly on a knife. The Model 10 was also more capable of removing fine staples with less damage to the supporting material.

One quart paint can : the Model 10's point was pressed the into the can and then a circular ring was cut off slicing around the can. The cutting was difficult, very hard to get through the seam. The edge was reflecting light in the entire contact region and fracture was evident. Under magnification the entire edge was basically broken away with chips about 0.1-0.2 mm in depth and one to two millimeters in length. This was repeated with a Howling Rat with a modified profile whose edge had been blended back into the primary grind. The Howing Rat cut the can much easier (didn't even notice the seam). No damage was visible by eye, near the tip some light was reflecting from the edge, under magnification the damage was 25% that of seen on the Model 10.

Frozen turkey and ham bones : with edges left from paint can cutting both knives were hacked into some bones. The turkey legs were 1.2 centimeters wide with two millimeter thick walls, the Ham bones were 2 centimeters wide with four to five millimeter thick walls. The chops were very forceful, the turkey bones were severed with one to two hits, and large pieces were broken out of the ham bone with every impact. The chops were cut into the bones on a 45 degree angle to minimize stress on the knife. The Model 10 took visible damage with every impact on the Turkey bone, chips clearly visible by eye, the largest was 0.018" thick at the back and 0.070" wide. On the ham bones the dents were smaller, about half as large, due to the decreased pressure from the wider contact area. No trouble in getting enough penetration to chop through either bone. The Howling Rat was not visibly effected on either bone chopping. It was then batoned into the ham bone with a 3 foot length of 2x4. This proved to be fairly difficult and a sloppy hit twisted the knife in the bone and chipped the edge. The fracture was 0.012" at the back of the bevel (very deep due to the modified very thin profile - 0.048").

Concrete block : the Model 10 knife was given some light chops into a concrete block, just using wrist flicks. The edge fractured readily, little or no impaction, the damage was on average from half to the 3/4 the width of the bevel. A very light poke into the block also readily fractured the tip.

Prying : after the edge was ground off with further cutting into the concrete the Model 10 was inserted into a wood block which was held into position with the off hand. With the right hand (actually done while sitting down), the knife bent easily to 75-85 degrees where it cracked violently. It was difficult to estimate the angle as the knife was wrapped due to the known sharding property. The four major pieces of the blade were all sub cracked into smaller fragments, much like glass. The edges were all sharp and able to cut skin readily. A shot :

Initiall a smooth steel was used to check the edge for alignment. The thread cutting performance did not significantly improve, however the length required to slice the poly dropped to 3.6 - 3.8 centimeters. Checking the blade on some meats and fats in the kitchen, a lot of slipping was still observed. The knife still had no ability to push cut cardboard and would just mash it down, slices were very rough. Thus it seems the standard tests of sharpness work decently well on the LM1 alloy.

A test was made with a few passes on a 22 degree jig to gauge the angle of the micro-bevel which was found to be steeper than 22 degrees. This additional bevel was removed with a 1000 grit waterstone. The metal worked easily compared to a few other knives in low alloy steels which also had to be sharpened. The polish was then raised with a 4000 grit waterstone and the edge then stropped on 0.5 micron chromium/aluminum oxide loaded leather, 10 passes per side. Total sharpening time was about twenty minutes.

The knife could now shave readily, just a hint of bite left from the 1000 grit stone indicating not enough honing was performed with the 4000 grit waterstone. The thread cutting ability was now 108 (13) grams. The edge was checked 12 hours later to confirm the sharpness was stable, it again tested very well 119 (44) grams and still shaved very smoothly. The large gain in sharpness made a significant improvement to the cutting ability. On the 3/8" manilla hemp rope the Model 10 now needed 24 (1) lbs on a rocking push cut through the tip and 37 (1) lbs through the choil. The slicing ability had also improved dramatically and only 15 (1) lbs were required on a two inch draw. The total gain in cutting performance was about 300 %.

For a comparison against a cutlery steel, after both were later extensively blunted, the Model 10 and Rucksack were honed with a 1000 grit waterstone to fully form an edge. Under magnification [x20] the edges showed the same micro-tooth pattern. The edges were then refined on a 4000 grit waterstone. Both looked identical again, the teeth were now on the level of being just being visible under magnification. The edges were refined with 0.5 micron chromium/aluminum oxide. The teeth were significantly reduced quickly on both blades. After a few passes on such loaded leather and then on plain leather both blades could shave arm hair when held at a 45 degree angle above the skin. The edge was also sharpened using a fine ceramic set at 22 degrees per side. With this edge the knife scored 93 (4) g on the light thread push cutting, and would again shave arm hair when held at a 45 degree angle above the skin. If desired the blade can also be filed.

The grip has four inches of functional width, the contouring is extensive and very specific. It fits the hand well both in a grip out on the tips of fingers with thumb on spine for precise work, as well as in a hammer grip. With the contouring reversed into the palm comfort is reduced but do to the radiusing, it isn't problematic. In general on a few pass arounds it recieved complaints of the finger grooves being less than optimal which is expected on a highly specific contour.

The spine is a bit sharp and excess pressure can be generated on deep cuts such as rocking through thick ropes or repeated cutting of very thick vegetables. The handle is also a flat on the bottom in the center swell (in the middle of the two screws in the above picture). With really heavy cutting this flat can be somewhat abrasive as the corners are high pressure contact points, this came out readily during the hardwood whittling. The end hook on the handle is too sharp for most use, and becomes abrasive quickly in partial finger grips for snap chopping. The Howling Rat is much more ergonomic in the same grip. On heavy stabs, the index finger cutout in the handle proved to be troublesome. It was too thin and almost pointy.

As an extreme, The Model 10 was used with liquid soap and water on the grip, it could still whittle wood fine, and chop readily, however regripping was frequently necessary and a lanyard hole would have been of benefit. Stabbing and hard hammering with the pommel was not possible, the hand would ramp over the grip readily. When vegetable oil was used, whittling and chopping were still possible however now regripping was necessary every 1-2 hits when chopping. Hard stabs could be done if the thumb was used on the pommel for stabilization, however with the blade facing outward (away from the body), the upper part of the pommel contacts the thumb and it is too squarish and is a high pressure point. If the blade is reversed then the thumb fits well over the sloped pommel, however the handle ergonomics as a whole are not that comfortable in such a grip as the index finger cutout faces towards the palm.

The Kydex sheath (0.055") is made in a pancake style, all seams match well and the edges are smooth. The blade locks in securely, taking ~8 lbs to draw. There is however some rattle in the tip region. It comes with a Blade-Tech TekLok attachment rigged for normal and cross draw wear. It can also be released from the belt or other rigging points by an opening of the belt loop. There is no secondary attachment system (snap webbing over the grip or similar).

The Model 10 came with a poorly formed edge which required sharpening before any precision cutting could be performed. It works well for light use due to the relative thin blade stock and thin edge which reduces wedging. It does especially well on food preparation due to the dropped blade and precision tip work due to the distal taper. The chopping ability is low due to the light weight and lack of blade balance. The handle ergonomics are about average, there are some problems with a few areas due to a lack of contouring this was especially noted during partial grip chopping and heavy stabs. The particular blade material, LM1, would rank near the top in regards to corrosion resistance and is easily capable of a very fine shaving edge, however in terms of edge holding or durability it was easily exceeded by even relatively "low end" steels. In regards to possible changes :

UPDATE : most of the above work was done with the edge at 15-16 degrees per side. The edge was made slightly more acute than the initial profile by a few degrees just because it was freehand sharpened and that is the usual angle honed.

Comments can be sent by email to : cliffstamp[REMOVE]@cutleryscience.com or by posting to the following thread :

| Last updated : | Feb 1 : 2006 |

| Originally written : | Fri Aug 29 11:14:11 NDT 2003 |