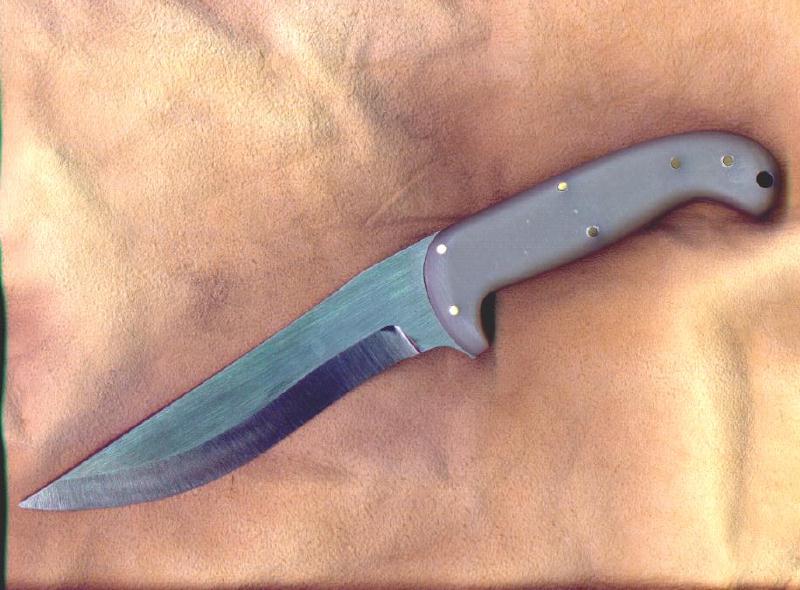

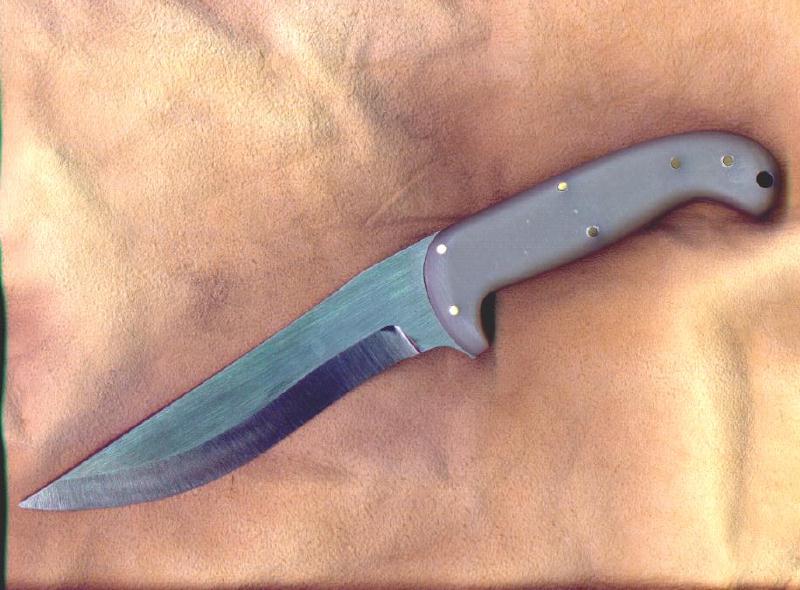

This blade came from a discussion between Martin Edgeworth and Ed Schott which produced this test blade out of 3V at 60 HRC :

The handle is G10 and the rest of the specs on the knife are as follows :

| Weight | Length | CG | Handle | Blade | Point | Bevel |

|---|---|---|---|---|---|---|

| Total / Blade / Handle | thickness / width | thickness / width | length | thickness / width | ||

| 412 | 31.0 / 15.4 / 9.0 | -2.3 | 2.2 / 3.1 | 0.4 / 3.4 | 1.7 | .40 / 1.30 |

Lengths are in cm, mass in g, CG is the center of gravity measured from the from of the grip. The handle measurements refer to about the middle.

UPDATE : Ed Schott is no longer making knives.

The handle is smooth, and a bit slippery. To insure retention the handle is both swelled and has a pronounced butt-hook and half guard. It is very comfortable at most light slicing work and as during heavy chopping. The butt-hook was not an issue due to the handle swell and overall light nature of the knife. The front half guard makes the grip stable even for reverse heavy thrusts at full strength into pine. The handle heavy balance also enhances grip security as well.

Ed sent the knife in used condition, these was little wear and no excessive folding or impaction or chips. It cut well but skipped a little on an attempt to shave arm hair. A couple of light strokes along the edge with an 800 grit ceramic rod set the edge back to shaving sharp.

As an accidently high stress, a friend dropped it and it hit the concrete floor edge first from about a height of 5 feet. The edge did not indent nor chip out. It cut nicely into the concrete floor and the net effect on the blade was that it just blunted. The tip impacted just enough to be visible.

The geometry has a number of advantages, mainly the angle of the blade, the recurve and of course the very thin edge. Compared to several other knives the 3V blade performed well :

The cutting ability of the very acute edge is high, very little force is required in use. The blade easily take slicing on soft metals like pop cans and can chop on hard woods without indenting or chipping out. The very thin edge wears down gradually and is easily restored with just a little work with a ceramic rod.

It is a bit fragile compare to the edge on some of the heavier knives, but their edges are significant more obtuse. However the tip bent readily with light prying in wood. One of the pins popped about 0.5 centimeters out of the handle slab. It was just hammered back in.

The knife has the common problem of single bevel grinds which is a vadtly reduced ease of sharpening as to maintain the origional profile the blade basically has to be finish polished with each sharpening. In general a higher flat grind with a secondary edge bevel of suitable angle is more efficient for sharpening and will also cut as well with greater durability.

This blade was later subjected to very heavy impacts with a framing hammer while the edge was against the shank of a screwdriver. The edge resisted fracture strongly and basically had to be torn apart. The knife as a whole seemed immune to fracture.

Comment can be sent to : cliffstamp[REMOVE]@cutleryscience.com.

For further information you might want to check the following review of this blade by Will Kwan :

| Last updated : | 02 : 10 : 2006 |

| Originally written: | 08 : 05 : 1999 |